Page 633 - Master Catalog 2017, Inch

P. 633

TopThread

™

Threading Selection Guide

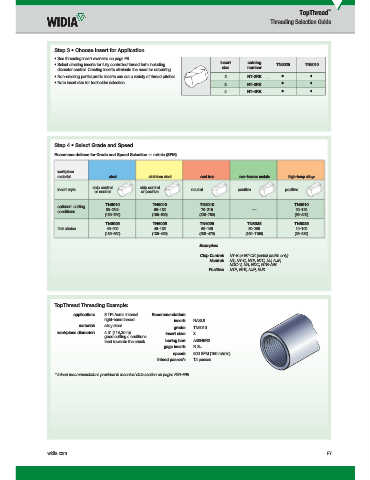

Step 3 • Choose Insert for Application

• See threading insert overview on page F8.

insert catalog

• Select cresting inserts for fully controlled thread form including size number TN6025 TN6010

diameter control. Cresting inserts eliminate the need for deburring.

• Non-cresting partial profi le inserts can cut a variety of thread pitches. 2 NT-2RK

• Note insert size for toolholder selection. 3 NT-3RK

4 NT-4RK

Step 4 • Select Grade and Speed

Recommendations for Grade and Speed Selection — m/min (SFM)

workpiece

material steel stainless steel cast iron non-ferrous metals high-temp alloys

chip control chip control

insert style neutral positive positive

or neutral or positive

TN6010 TN6010 TN6010 TN6010

optimum cutting 50–230n 50–185 70–210 — 20–120

conditions

(160–750) (160–600) (230–700) (65–400)

TN6025 TN6025 TN6025 TN6025 TN6025

fi rst choice 40–200 40–135 60–145 50–360 10–100

(130–650) (130–450) (200–475) (160–1150) (35–330)

Examples:

Chip Control: NT-K or NT-CK (partial profi le only)

Neutral: NT, NT-C, NTF, NTC, NJ, NJF,

NDC-V, NA, NDC, NTB-A/B

Positive: NTP, NTK, NJP, NJK

TopThread Threading Example:

application: 8 TPI Acme internal Recommendation:

right-hand thread

insert: NA3L8

material: alloy steel

grade: TN6010

workpiece diameter: 4.5" (114,3mm) insert size: 3

good cutting c onditions

feed towards the chuck boring bar: A40NER3

gage insert: N.3L

speed: 500 SFM (150 m/min)

infeed passes*: 12 passes

* Infeed recommendations provided in technical data section on pages F90–F95.

widia.com F7

WID_Master16_Turning_Threading_F006_F007_Minch_REBRAND.indd 7 L V i WID M 16 T i Th di F006 F007 Mi h REBRANDN b 102015752AM

11/10/15 11:15 AM