Page 635 - Master Catalog 2017, Inch

P. 635

TopThread

™

Grades and Grade Descriptions

P Steel

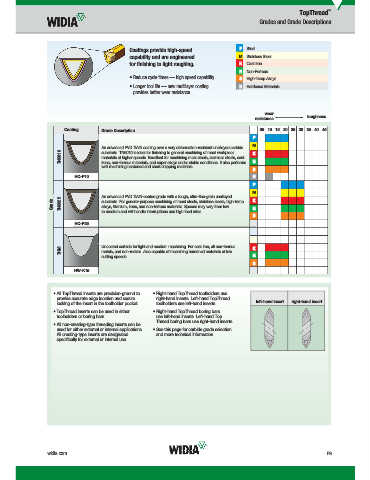

Coatings provide high-speed

capability and are engineered M Stainless Steel

for finishing to light roughing. K Cast Iron

N Non-Ferrous

• Reduce cycle times — high speed capability. S High-Temp Alloys

• Longer tool life — new multilayer coating H Hardened Materials

provides better wear resistance.

wear toughness

resistance

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

An advanced PVD TiAlN coating over a very deformation-resistant unalloyed carbide M

TN6010 materials at higher speeds. Excellent for machining most steels, stainless steels, cast K

substrate. TN6010 is ideal for fi nishing to general machining of most workpiece

N

irons, non-ferrous materials, and super alloys under stable conditions. It also performs

well machining hardened and short chipping materials.

S

HC-P10 H

P

M

An advanced PVD TiAlN-coated grade with a tough, ultra-fi ne-grain unalloyed

Grade TN6025 substrate. For general-purpose machining of most steels, stainless steels, high-temp K

alloys, titanium, irons, and non-ferrous materials. Speeds may vary from low

to medium and will handle interruptions and high feed rates. N

S

HC-P25

Uncoated carbide for light and medium machining. For cast iron, all non-ferrous K

THM metals, and non-metals. Also capable of machining hardened materials at low

cutting speeds. N

S

HW-K15

• All TopThread inserts are precision-ground to • Right-hand TopThread toolholders use

provide accurate edge location and secure right-hand inserts. Left-hand TopThread

locking of the insert in the toolholder pocket. toolholders use left-hand inserts. left-hand insert right-hand insert

• TopThread inserts can be used in either • Right-hand TopThread boring bars

toolholders or boring bars. use left-hand inserts. Left-hand Top

Thread boring bars use right-hand inserts.

• All non-cresting-type threading inserts can be

used for either external or internal applications. • See this page for carbide grade selection

All cresting-type inserts are designated and more technical information.

specifi cally for external or internal use.

widia.com F9

WID_Master16_Turning_Threading_F008_F009_Minch_REBRAND.indd 9 L V i WID M 16 T i Th di F008 F009 Mi h REBRANDO b 152015830AM

10/30/15 2:11 PM