Page 728 - Master Catalog 2017, Inch

P. 728

Technical Information

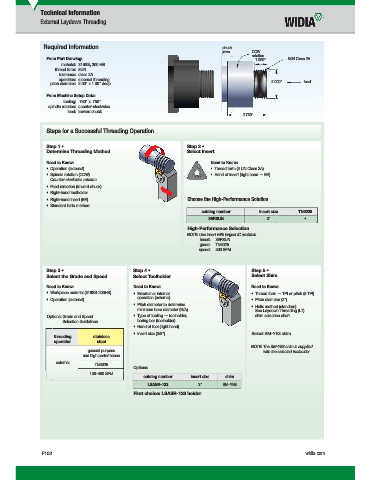

External Laydown Threading

Required Information chuck

jaws CCW

rotation

From Part Drawing: 1.000" 8UN Class 2A

material: 316SS, 200 HB

thread form: 8UN

tolerance: class 2A

operation: external threading 2.000"

pitch diameter: 2.00" x 1.00" deep feed

From Machine Setup Data:

tooling: .750" x .750"

spindle rotation: counter-clockwise

feed: toward chuck

2.750"

Steps for a Successful Threading Operation

Step 1 • Step 2 •

Determine Threading Method Select Insert

Need to Know: Need to Know:

• Operation (external). • Thread form (8 UN Class 2A).

• Spindle rotation (CCW). • Hand of insert (right hand — ER).

Counter-clockwise rotation.

• Feed direction (toward chuck).

• Right-hand toolholder.

• Right-hand insert (ER). Choose the High-Performance Solution

• Standard helix method.

catalog number insert size TN6025

3ER8UN 3" •

High-Performance Selection

NOTE: Use insert with largest iC available.

insert: 3ER8UN

grade: TN6025

speed: 500 SFM

Step 3 • Step 4 • Step 5 •

Select the Grade and Speed Select Toolholder Select Shim

Need to Know: Need to Know: Need to Know:

• Workpiece material (316SS-200HB). • External or internal • Thread form — TPI or pitch (8 TPI).

operation (external).

• Operation (external). • Pitch diameter (2").

• Pitch diameter to determine • Helix method (standard).

minimum bore diameter (N/A).

See Laydown Threading (LT)

Options: Grade and Speed • Type of tooling — toolholder, shim selection chart.

Selection Guidelines boring bar (toolholder).

• Hand of tool (right hand).

• Insert size (3/8"). Select SM-YE3 shim

threading stainless

operation steel

NOTE: The SM-YE3 shim is supplied

general purpose with the selected toolholder.

and high performance

external

TN6025

Options:

150–450 SFM

catalog number insert size shim

LSASR-123 3" SM-YE3

First choice: LSASR-123 holder

F102 widia.com

WID M

i

V

Th

i

di

F102 F103 Mi

16 T

L WID_Master16_Turning_Threading_F102_F103_Minch_REBRAND.indd 102 h REBRAND N b 9 2015 4 06 PM 11/12/15 4:31 PM