Page 23 - final

P. 23

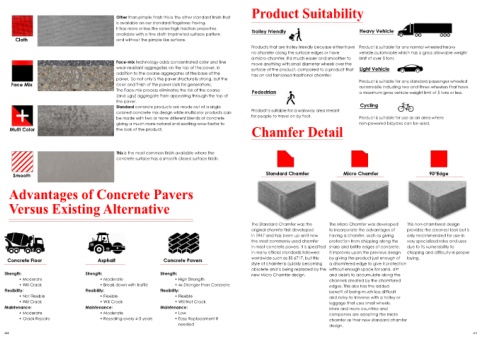

Product Suitability

Other than pimple finish this is the other standard finish that

is available on our standard Flagstone Paving.

It has more or less the same high traction properties Trolley Friendly Heavy Vehicle

available with a fine cloth imprineted surface pattern

Cloth and without the pimple like surface.

Products that are trolley friendly becuase either have Product is suitable for any normal wheeled heavy

no chamfer along the surface edges or have vehicle,automobile which has a gross allowable weight

a micro-chamfer, It is much easier and smoother to limit of over 5 tons

Face-mix technology adds concentrated color and fine move anything with small diameter wheels over the

wear-resistant aggregates on the top of the paver, in surface of the product, compared to a product that Light Vehicle

addition to the coarse aggregates at the base of the has an old fashioned traditional chamfer.

paver. So not only is the paver structurally strong, but the Product is suitable for any standard passenger wheeled

Face Mix color and finish of the paver lasts for generations. automobile including two and three wheelers that have

The Face-mix process eliminates the risk of the coarse Pedestrian a maximum gross vehicle weight limit of 5 tons or less.

(and ugly) aggregate from appearing through the top of

the paver.

Standard concrete products are made out of a single Cycling

colored concrete mix design while multicolor products can Product is suitable for a walkway area meant

be made with two or more different blends of concrete for people to travel on by foot. Product is suitable for use as an area where

giving a much more natural and exciting wow factor to non-powered bicycles can be used.

Multi Color the look of the product. Chamfer Detail

This is the most common finish available where the

concrete surface has a smooth closed surface finish.

Smooth Standard Chamfer Micro Chamfer 90°Edge

Advantages of Concrete Pavers

Versus Existing Alternative

The Standard Chamfer was the The Micro Chamfer was developed This non-chamfered design

original chamfer first developed to incorporate the advantages of provides the cleanest look but is

in 1947 and has been up until now having a chamfer, such as giving only recommended for use in

the most commonly used chamfer protection from chipping along the very specialized roles and uses

in most concrete pavers. It is specified sharp and brittle edges of concrete. due to its vulnerability to

in many official standards followed It improves upon the previous design chipping and difficulty in proper

Concrete Floor Asphalt Concrete Pavers worldwide such as BS 6717, but this by giving the product just enough of laying.

style of chamfer is quickly becoming a chamfered edge to give it protection

obsolete and is being replaced by the without enough space for sand, dirt

Strength: Strength: Strength: new Micro Chamfer design. and debris to accumulate along the

• Moderate • Moderate • High Strength channels created by the chamfered

• Will Crack • Break down with traffic • 4x Stronger then Concrete edges. This also has the added

Flexibility: Flexibility: Flexibility: benefit of being much less difficult

• Not Flexible • Flexible • Flexible and noisy to traverse with a trolley or

• Will Crack • Will Crack • Will Not Crack luggage that uses small wheels.

Maintenance: Maintenance: Maintenance: More and more countries and

• Moderate • Moderate • Low companies are adopting the micro

• Crack Repairs • Resealing every 4-5 years • Easy Replacement if chamfer as their new standard chamfer

needed design.

44 45