Page 33 - millerwelds catalog_2022

P. 33

A FLE22 Cat P 33 Automation.qxp_Automation 1/20/22 7:06 PM Page 1

Automation

To order Jetline automation solutions: Call 1-630-653-6819 or email JetlineSales@MillerWelds.com

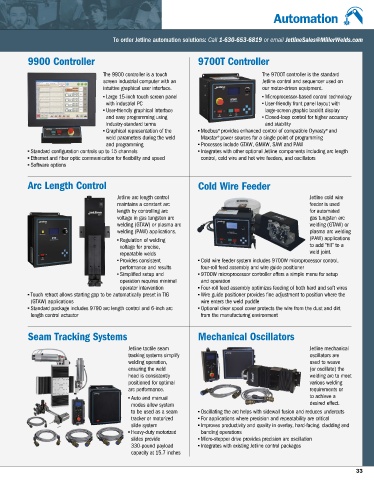

9900 Controller 9700T Controller

The 9900 controller is a touch The 9700T controller is the standard

screen industrial computer with an Jetline control and sequencer used on

intuitive graphical user interface. our motor-driven equipment.

Large 15-inch touch screen panel Microprocessor-based control technology

with industrial PC User-friendly front panel layout with

User-friendly graphical interface large-screen graphic backlit display

and easy programming using Closed-loop control for higher accuracy

industry-standard terms and stability

Graphical representation of the Modbus ® provides enhanced control of compatible Dynasty ® and

weld parameters during the weld Maxstar ® power sources for a single point of programming

and programming Processes include GTAW, GMAW, SAW and PAW

Standard configuration controls up to 15 channels Integrates with other optional Jetline components including arc length

Ethernet and fiber optic communication for flexibility and speed control, cold wire and hot wire feeders, and oscillators

Software options

Arc Length Control Cold Wire Feeder

Jetline arc length control Jetline cold wire

maintains a constant arc feeder is used

length by controlling arc for automated

voltage in gas tungsten arc gas tungsten arc

welding (GTAW) or plasma arc welding (GTAW) or

welding (PAW) applications. plasma arc welding

Regulation of welding (PAW) applications

voltage for precise, to add “fill” to a

repeatable welds weld joint.

Provides consistent Cold wire feeder system includes 9700W microprocessor control,

performance and results four-roll feed assembly and wire guide positioner

Simplified setup and 9700W microprocessor controller offers a simple menu for setup

operation requires minimal and operation

operator intervention Four-roll feed assembly optimizes feeding of both hard and soft wires

Touch retract allows starting gap to be automatically preset in TIG Wire guide positioner provides fine adjustment to position where the

(GTAW) applications wire enters the weld puddle

Standard package includes 9790 arc length control and 6-inch arc Optional clear spool cover protects the wire from the dust and dirt

length control actuator from the manufacturing environment

Seam Tracking Systems Mechanical Oscillators

Jetline tactile seam Jetline mechanical

tracking systems simplify oscillators are

welding operation, used to weave

ensuring the weld (or oscillate) the

head is consistently welding arc to meet

positioned for optimal various welding

arc performance. requirements or

Auto and manual to achieve a

modes allow system desired effect.

to be used as a seam Oscillating the arc helps with sidewall fusion and reduces undercuts

tracker or motorized For applications where precision and repeatability are critical

slide system Improves productivity and quality in overlay, hard-facing, cladding and

Heavy-duty motorized banding operations

slides provide Micro-stepper drive provides precision arc oscillation

330-pound payload Integrates with existing Jetline control packages

capacity at 15.7 inches

33