Page 6 - millerwelds catalog_2022

P. 6

A FLE22 Cat P 06 MIG Intro.qxp_MIG Intro 1/20/22 6:54 PM Page 1

For more detailed

MIG GMAW information, visit

Also see Multiprocess section for machines that can MIG weld. MillerWelds.com/mig

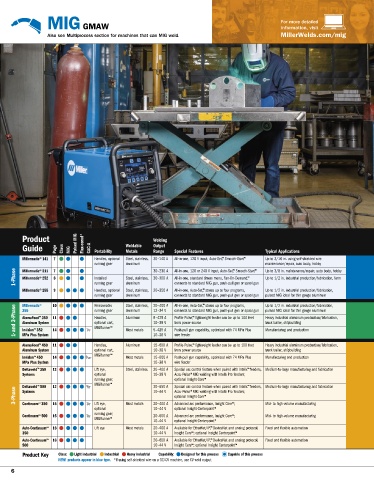

Product Pulsed MIG Flux-cored* Welding

Weldable Output

Guide Page Class MIG CAC-A Portability Metals Range Special Features Typical Applications

Handles, optional Steel, stainless, 30–140 A All-in-one, 120 V input, Auto-Set, ™ Smooth-Start ™ Up to 3/16 in. using self-shielded wire

Millermatic® 141 7

running gear aluminum maintenance/repair, auto body, hobby

1-Phase Millermatic® 211 7 Installed Steel, stainless, 30–300 A All-in-one, standard timers menu, Fan-On-Demand, ™ Up to 1/2 in. industrial production/fabrication, farm

30–230 A All-in-one, 120 or 240 V input, Auto-Set, ™ Smooth-Start ™ Up to 3/8 in. maintenance/repair, auto body, hobby

Millermatic® 252 8

running gear aluminum connects to standard MIG gun, push-pull gun or spool gun

Millermatic® 255 9 Handles, optional Steel, stainless, 20–350 A All-in-one, Auto-Set, ™ stores up to four programs, Up to 1/2 in. industrial production/fabrication,

Millermatic® 10 running gear aluminum connects to standard MIG gun, push-pull gun or spool gun pulsed MIG ideal for thin gauge aluminum

Removeable Steel, stainless, 20–400 A All-in-one, Auto-Set, ™ stores up to four programs, Up to 1/2 in. industrial production/fabrication,

1- and 3-Phase 355 1 ⁄4" running gear aluminum 12–34 V connects to standard MIG gun, push-pull gun or spool gun pulsed MIG ideal for thin gauge aluminum

Handles, Aluminum 5–425 A Profile Pulse, ™ lightweight feeder can be up to 100 feet Heavy industrial aluminum production/fabrication,

AlumaFeed ™ 350 11

Aluminum System

optional cart, 10–38 V from power source truck trailer, shipbuilding

MIGRunner ™

Most metals 5–425 A Push-pull gun capability, optimized with 74 MPa Plus Manufacturing and production

Invision ™ 352 14

MPa Plus System

10–38 V wire feeder

AlumaFeed ™ 450 11 Handles, Aluminum 15–600 A Profile Pulse, ™ lightweight feeder can be up to 100 feet Heavy industrial aluminum production/fabrication,

Aluminum System optional cart, 10–38 V from power source truck trailer, shipbuilding

Invision ™ 450 14 MIGRunner ™ Most metals 15–600 A Push-pull gun capability, optimized with 74 MPa Plus Manufacturing and production

5 ⁄16"

MPa Plus System 10–38 V wire feeder

Deltaweld ™ 350 12 Lift eye, Steel, stainless 20–400 A Special arc control feature when paired with Intellx ™ feeders, Medium-to-large manufacturing and fabrication

Systems optional 10–38 V Accu-Pulse® MIG welding with Intellx Pro feeders;

Deltaweld ™ 500 12 running gear, optional Insight Core ™

MIGRunner ™

3

30–650 A Special arc control feature when paired with Intellx ™ feeders, Medium-to-large manufacturing and fabrication

3-Phase Systems ⁄8" 10–44 V Accu-Pulse® MIG welding with Intellx Pro feeders;

optional Insight Core ™

1

⁄4"

Continuum ™ 350 15 Lift eye, Most metals 20–400 A Advanced arc performance, Insight Core ™; Mid- to high-volume manufacturing

optional 10–44 V optional Insight Centerpoint ™

Continuum ™ 500 15 running gear, 20–600 A Advanced arc performance, Insight Core ™; Mid- to high-volume manufacturing

3

⁄8"

MIGRunner ™ 10–44 V optional Insight Centerpoint ™

Auto-Continuum ™ 16 Lift eye Most metals 20–400 A Available for EtherNet/IP, ™ DeviceNet and analog protocol, Fixed and flexible automation

350 10–44 V Insight Core ™; optional Insight Centerpoint ™

Auto-Continuum ™ 16 20–600 A Available for EtherNet/IP, ™ DeviceNet and analog protocol, Fixed and flexible automation

500 10–44 V Insight Core ™; optional Insight Centerpoint ™

Product Key Class: Light industrial Industrial Heavy industrial Capability: Designed for this process Capable of this process

NEW! products appear in blue type. *If using self-shielded wire on a CC/CV machine, use CV weld output.

6