Page 112 - NEW Armstrong Book - 2

P. 112

(a)

(b)

(c)

FIGURE 5: THREE-PHASE FAST BATTERY-CHARGING CONFIGURATIONS HIGHLIGHT THE ADVANTAGE OF USING SiC MOSFETS.

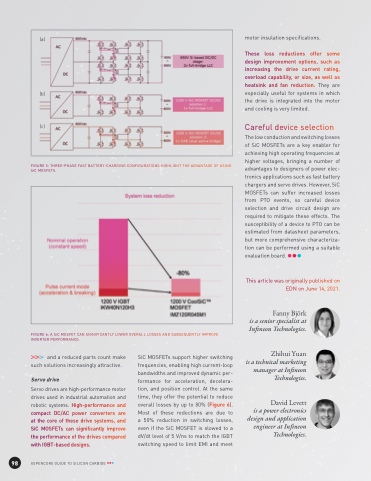

FIGURE 6: A SiC MOSFET CAN SIGNIFICANTLY LOWER OVERALL LOSSES AND SUBSEQUENTLY IMPROVE INVERTER PERFORMANCE.

These loss reductions offer some design improvement options, such as increasing the drive current rating, overload capability, or size, as well as heatsink and fan reduction. They are especially useful for systems in which the drive is integrated into the motor and cooling is very limited.

Careful device selection

The low conduction and switching losses of SiC MOSFETs are a key enabler for achieving high operating frequencies at higher voltages, bringing a number of advantages to designers of power elec- tronics applications such as fast battery chargers and servo drives. However, SiC MOSFETs can suffer increased losses from PTO events, so careful device selection and drive circuit design are required to mitigate these effects. The susceptibility of a device to PTO can be estimated from datasheet parameters, but more comprehensive characteriza- tion can be performed using a suitable evaluation board.

This article was originally published on EDN on June 14, 2021.

Fanny Björk

is a senior specialist at Infineon Technologies.

Zhihui Yuan

is a technical marketing manager at Infineon Technologies.

David Levett

is a power electronics design and application engineer at Infineon Technologies.

motor insulation specifications.

and a reduced parts count make such solutions increasingly attractive.

Servo drive

Servo drives are high-performance motor drives used in industrial automation and robotic systems. High-performance and compact DC/AC power converters are at the core of these drive systems, and SiC MOSFETs can significantly improve the performance of the drives compared with IGBT-based designs.

SiC MOSFETs support higher switching frequencies, enabling high current-loop bandwidths and improved dynamic per- formance for acceleration, decelera- tion, and position control. At the same time, they offer the potential to reduce overall losses by up to 80% (Figure 6). Most of these reductions are due to a 50% reduction in switching losses, even if the SiC MOSFET is slowed to a dV/dt level of 5 V/ns to match the IGBT switching speed to limit EMI and meet

98

ASPENCORE GUIDE TO SILICON CARBIDE