Page 25 - Sorcha Mathews

P. 25

MATERIAL

INFORMATION Faux Replication Reflection/ Trial + Error

Prevalence Historical Use Contextual Use Trial 1 lacquered finish because it

I initially wanted to create a would be easier to cover a large

Copper and brushed Since prehistoric times Today copper is being used polished copper finish. I set out surface in lacquer than nail

copper finishes are copper has been widely more and more often in to do this with some chrome polish.

currently trending in interi- used for both functional and decorative household powder i had for nail art ( i

or design and product decorative purposes due to products and kitchen ware would have bought a copper Reflection

design. It compliments it being malleable, ductile including light fixtures, coloured powder if this worked. The powder wouldnt properly

adhere to lacquer, it would only

It is typically used on gel nails

neutral colours by adding a and a great conductor of cookware and ornaments. but i tested it on some normal go on it patches with excessive

tone of warmth and draws heat. Some of its uses It is also used in luxury nail polish and it worked rubbing.

the eye to points of inter- included kitchenware, items, but ones that perfectly, you just have to rub

est. It has an aesthetic that wiring, currency and tools wouldn’t get much wear the powder into the dried polish Learning:

with an applicator. I tried

Chrome nail powder doesnt

can fit in with modern amongst other things. due to coppers maleable rubbing the powder into a work on spray lacquer.

BRUSHED COPPER styled products, and prod- state. Trial 2

ucts made to look aged.

Knowing the chrome powder Learning:

The powder would only work on

PRODUCTION worked on nail polish i tried to polish or gel that wasnt sanded.

get an even coat of polish on an

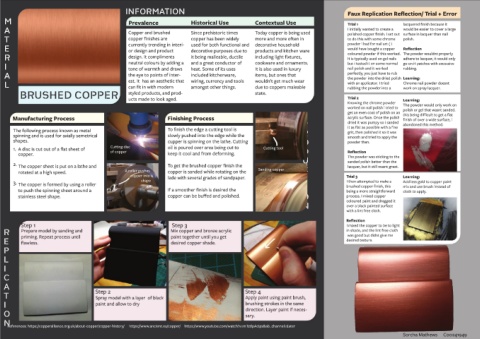

Manufacturing Process Finishing Process acrylic surface. Once the polish this being difficult to get a flat

finish of over a wide surface, i

dried it was pumpy so i sanded abandoned this method.

The following process known as metal To finish the edge a cutting tool is it as flat as possible with a fine

grit, then polished it so it was

spinning and is used for axially semetrical slowly pushed into the edge while the smooth and tried to apply the

shapes. cupper is spinning on the lathe. Cutting powder then.

1. A disc is cut out of a flat sheet of Cutting disc oil is poured over area being cut to Cutting tool

copper. of copper keep it cool and from deforming. Reflection

The powder was sticking to the

2. The copper sheet is put on a lathe and To get the brushed copper finish the sanded polish better than the

lacquer, but it still wasnt great.

rotated at a high speed. A roller pushes copper is sanded while rotating on the Sanding copper

copper into lade with several grades of sandpaper. Trial 3 Learning:

3. The copper is formed by using a roller shape I then attempted to make a Add less gold to copper paint

to push the spinning sheet around a If a smoother finish is desired the brushed copper finish, this mix and use brush instead of

being a more straightforward

cloth to apply.

stainless steel shape. copper can be buffed and polished. process. I mixed copper

coloured paint and dragged it

over a black painted surface

with a lint free cloth.

REPLICATION Reflection

Step 1 Step 3 I mixed the copper to be to light

Prepare model by sanding and Mix copper and bronze acrylic in shade, and the lint free cloth

priming. Repeat process until paint together until you get was good but didnt give me

flawless. desired copper shade. desired texture.

Step 2 Step 4

Spray model with a layer of black Apply paint using paint brush,

paint and allow to dry brushing strokes in the same

direction. Layer paint if neces-

sary.

References: https://copperalliance.org.uk/about-copper/copper-history/ https://www.ancient.eu/copper/ https://www.youtube.com/watch?v=mTztlpAcips&ab_channel=Eater

Sorcha Mathews C00241949