Page 24 - Sorcha Mathews

P. 24

MATERIAL

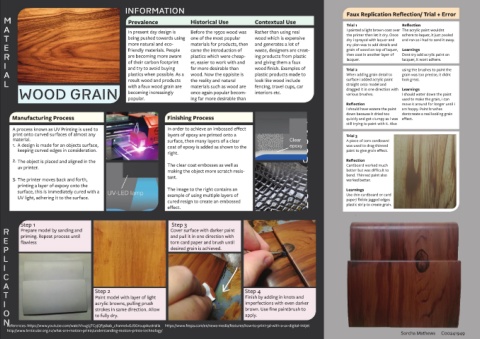

INFORMATION Faux Replication Reflection/ Trial + Error

Prevalence Historical Use Contextual Use Trial 1 Reflection

In present day design is Before the 1950s wood was Rather than using real I painted a light brown coat over The acrylic paint wouldnt

being pushed towards using one of the most popular wood which is expensive the primer then let it dry. Once adhere to laquer, it just pooled

dry i sprayed with laquer and

and ran so i had to sand it away.

more natural and eco- materials for products, then and generates a lot of my plan was to add details and

friendly materials. People came the introduction of waste, designers are creat- grain of wood on top of laquer, Learnings

are becoming more aware plastics which were cheap- ing products from plastic then coat in another layer of Dont try add acrylic paint on

of their carbon footprint er, easier to work with and and giving them a faux lacquer. lacquer, it wont adhere.

and try to avoid buying far more desirable than wood finish. Examples of Trial 2 using the brushes to paint the

plastics when possible. As a wood. Now the oppisite is plastic products made to When adding grain detail to grain was too precise, it didnt

result wood and products the reality and natural look like wood include surface i added acrylic paint look great.

straight onto model and

with a faux wood grain are

fencing, travel cups, car

materials such as wood are

WOOD GRAIN becoming increasingly once again popular becom- interiors etc. dragged it in one direction with Learnings

I should water down the paint

various brushes.

ing far more desirable than

popular.

used to make the grain, i can

PRODUCTION Reflection move it around for longer until i

am happy. Paint brushes

I should have watere the paint

Manufacturing Process Finishing Process down because it dried too dontcreate a real looking grain

effect.

quickly and got clumpy as i was

still trying to paint with it. Also

A process known as UV Printing is used to In order to achieve an imbossed effect

print onto curved surfaces of almost any layers of epoxy are printed onto a Trial 3

material. surface, then many layers of a clear Clear A piece of torn cardboard

1. A design is made for an objects surface, coat of epoxy is added as shown to the epoxy was used to drag thinned

keeping curved edges in consideration. paint to give grain effect.

right.

2. The object is placed and aligned in the Reflection

uv printer. The clear coat embosses as well as Cardboard worked much

making the object more scratch resis- better but was difficult to

3. The printer moves back and forth, tant. bend. Thinned paint also

worked better.

printing a layer of expoxy onto the

surface, this is immediately cured with a The image to the right contains an Learnings

UV light, adhering it to the surface. example of using multiple layers of Use thin cardboard or card

cured resign to create an embossed paper/ flxible jagged edges

effect. plastic strip to create grain.

REPLICATION

Step 1 Step 3

Prepare model by sanding and Cover surface with darker paint

priming. Repeat process until and pull it in one direction with

flawless torn card paper and brush until

desired grain is achieved.

Step 2 Step 4

Paint model with layer of light Finish by adding in knots and

acrylic browns, pulling prush imperfections with even darker

strokes in same direction. Allow brown. Use fine paintbrush to

to fully dry. apply.

References: https://www.youtube.com/watch?v=gi3TCyjQf3s&ab_channel=GJSGroupAustralia https://www.fespa.com/en/news-media/features/how-to-print-3d-with-a-uv-digital-inkjet

http://www.lenticular.org.nz/what-are-motion-prints/understanding-motion-prints-technology/

Sorcha Mathews C00241949