Page 20 - Portfolio 2024 – Samuel Skurka_Year 1

P. 20

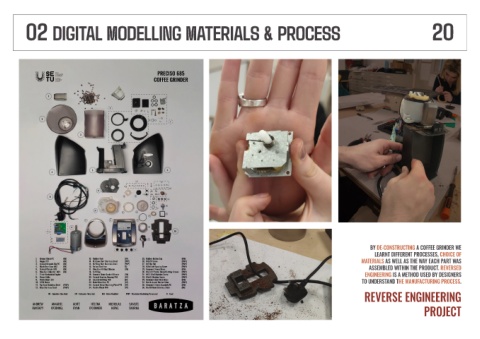

02 DIGITAL MODELLING MATERIALS & PROCESS 20

PRECISO 685

COFFEE GRINDER

1

6

2

7

3

5 4

4

27

28 29

26

30

23

31 32 33

8 24 25

35

36

34

20

21 22

19

18

11 12 17

10 15

9 16

14

BY DE-CONSTRUCTING A COFFEE GRINDER WE

13

LEARNT DIFFERENT PROCESSES, CHOICE OF

1. Ground ChutePC (IM) 13. Rubber Foot (IM) 25. Rubber Button Cap (BM)

2. Hopper PC (IM) 14. M3 Cone Burr Stainless Steel (PMP) 26. M3x20 Screw (PMP) MATERIALS AS WELL AS THE WAY EACH PART WAS

3. Conical Grounds Bin PC (IM) 15. M2 Ring Burr Stainless Steel (PMP) 27. M3 Hex Nut (PMP)

4. Black Rear Case ABS (IM) 16. Ballast Cast Iron (C) 28. M2x6 Self Tapping Screw (PMP) ASSEMBLED WITHIN THE PRODUCT. REVERSED

5. Conical Chassis ABS (IM) 17. Ring Burr O-Ring Silicone (EM) 29. Grommet Sleeve Brass (BM)

6. Ring Burr Adjuster ABS (IM) 18. Felt Ring 30. M3.5x11 Plastic Thread Cutting Screws (PMP)

7. Timer Mechanical Engine 19. Grounds Chute Gasket Silicone (EM) 31. M6-1.25x8 Machine Screw (PMP) ENGINEERING IS A METHOD USED BY DESIGNERS

8. Power Cable 20. Conical Gearbox Housing PA6 (IM) 32. M5x12 Machine Screw (PMP)

9. Power Board Set 21. Adjustment Ring PA6 (IM) 33. Grommet Gear Male Brass (BM)

10. 230V Motor 22. Main Drive Gear PC (IM) 34. Hex Nuts and Washer Shim (PMP) TO UNDERSTAND THE MANUFACTURING PROCESS.

11. Top Case Stainless Steel (PMP) 23. Conical Motor Mounting Plate PPS (IM) 35. Grommet Sleeve Assembly PC (BM)

12. Base Stainless Steel (PMP) 24. Paddle Wheel PA6 (IM) 36. On/Off Knob Stainless Steel (IM)

REVERSE ENGINEERING

IM - Injection Moulded EM - Extrusion Moulded BM - Blow Moulded PMP - Precision Machining Processed C - Cast

ANDREW ANNABEL AOIFE HELENA NICHOLAS SAMUEL

PROJECT

RAVSKYY O’CONNEL RYAN O’CONNOR HOWE SKURKA