Page 47 - Luke Lister

P. 47

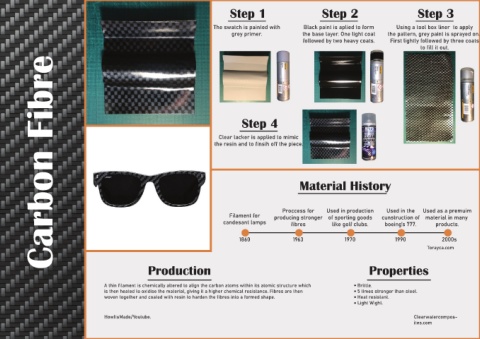

Step 1 Step 2 Step 3

The swatch is painted with Black paint is aplied to form Using a tool box liner to apply

grey primer. the base layer. One light coat the pattern, grey paint is sprayed on.

followed by two heavy coats. First lightly followed by three coats

to fill it out.

Carbon Fibre

Step 4

Clear lacker is applied to mimic

the resin and to finsih off the piece.

Material History

Proccess for Used in production Used in the Used as a premuim

Filament for producing stronger of sporting goods cunstruction of material in many

candesant lamps fibres like golf clubs. boeing’s 777. products.

1860 1963 1970 1990 2000s

Torayca.com

Production Properties

A thin filament is chemically altered to align the carbon atoms within its atomic structure which Brittle.

is then heated to oxidise the material, giving it a higher chemical resistance. Fibres are then 5 times stronger than steel.

woven together and coated with resin to harden the fibres into a formed shape. Heat resistant.

Light Wight.

HowItsMade/Youtube. Clearwatercompos-

ites.com