Page 9 - Timber_Log_Buildings.serifbackup

P. 9

Timber - a fractured approach

The architectural sector is gradually beginning to understand the benefits of timber that companies such as Ritsu

have long known, but as stated earlier in this document use tends to revolve around the use of the more novel

forms of timber in large scale structures such as offices, colleges rather than in ordinary homes. Family and

retirement homes do get a look in but these are mostly self-build projects, one-off designs - not main stream

solutions.

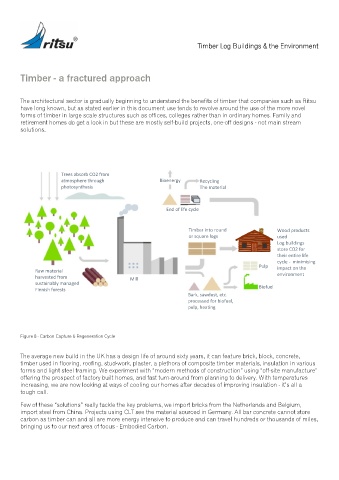

Trees absorb CO2 from

atmosphere through Bioenergy Recycling

photosynthesis The material

End of life cycle

Timber into round Wood products

or square logs used

Log buildings

store CO2 for

their entire life

cycle - minimising

Pulp impact on the

Raw material

harvested from Mill environment

sustainably managed

Finnish forests Biofuel

Bark, sawdust, etc.

processed for biofuel,

pulp, heating

Figure 8 - Carbon Capture & Regeneration Cycle

The average new build in the UK has a design life of around sixty years, it can feature brick, block, concrete,

timber used in flooring, roofing, stud-work, plaster, a plethora of composite timber materials, insulation in various

forms and light steel framing. We experiment with “modern methods of construction” using “off-site manufacture”

offering the prospect of factory built homes, and fast turn-around from planning to delivery. With temperatures

increasing, we are now looking at ways of cooling our homes after decades of improving insulation - it’s all a

tough call.

Few of these “solutions” really tackle the key problems, we import bricks from the Netherlands and Belgium,

import steel from China. Projects using CLT see the material sourced in Germany. All bar concrete cannot store

carbon as timber can and all are more energy intensive to produce and can travel hundreds or thousands of miles,

bringing us to our next area of focus - Embodied Carbon.