Page 64 - RUST-OLEUM PRODUCT CATALOG (July 2014) 100-PAGES

P. 64

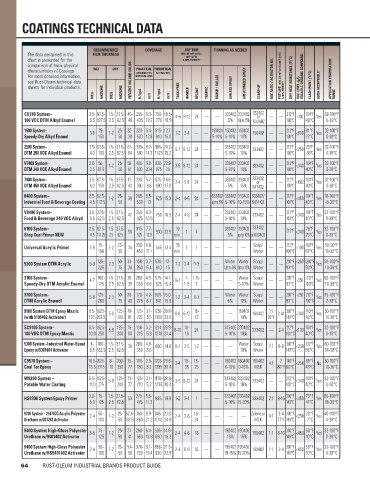

COATINGS TECHNICAL DATA

RECOMMENDED COVERAGE DRY TIME THINNING AS NEEDED

The data contained in this FILM THICKNESS HRS. AT 70˚F (21˚C)–

80˚F (27˚C)

chart is presented for the & 50% HUMIDITY

comparison of basic physical

characteristics of Coatings. WET DRY PRACTICAL THEORETICAL

AT 1 MIL DFT.

ASSUMES 15%

For more detailed information, MATERIAL LOSS POT LIFE HRS. AT 70˚F (21˚C)–80˚F (27˚C) DRY HEAT RESISTANCE (˚F/˚C) VOLATILE ORGANIC COMPOUND APPLICATION TEMPERATURE

see Rust-Oleum technical data PERCENT VOLUME SOLIDS AIR-ATOMIZED SPRAY MIX RATIO / ACTIVATOR NO.

sheets for individual products. TACK-FREE BRUSH / ROLLER AIRLESS SPRAY & 50% HUMIDITY VOC LEVEL (g/l) FLASH POINT (˚F/˚C) USDA ACCEPTABLE 1

MILS MICRONS MILS MICRONS ft. 2 /gal. m 2 /l ft. 2 /gal. m 2 /l HANDLE RECOAT TRAFFIC CLEAN-UP RANGE

CV740 System– 3.5- 87.5- 1.5- 37.5- 46- 255- 6.3- 750- 18.5- 4-6 8-12 24 — — 333402 333402 333402 — — 212°F <100 104°F Yes 32-100°F

or

100 VOC DTM Alkyd Enamel 5.5 137.5 2.5 62.5 48 435 10.7 770 18.9 5% Up to 15% 633402 100°C 40°C 0-38°C

1500 System– 3-6 75- 1-2 25- 32- 220- 5.4- 515- 12.7- 1-2 2-4 — — 1504024 150402 150402 150402 — — 212°F <600 81°F Yes 32-100°F

Speedy-Dry Alkyd Enamel 150 50 38 520 12.8 610 15.0 5-10% 5-10% 10% 100°C 27°C 0-38°C

2500 System– 2.5- 62.5- 1.5- 37.5- 61- 335- 8.2- 985- 24.2- 5-7 8-12 24 — — 333402 333402 333402 — — 212°F <250 23°F Yes 32-100°F

DTM 250 VOC Alkyd Enamel 4.0 100 2.5 62.5 64 580 14.3 1023 25.2 5-10% 10% 100°C -50°C 0-38°C

V7400 System– 2.0- 50- 1-2 25- 58- 400- 9.8- 930- 22.9- 3-5 8-12 24 — — 333402 333402 333402 — — 212°F <340 104°F Yes 32-100°F

DTM 340 VOC Alkyd Enamel 3.5 87.5 50 61 830 20.4 975 24 5-10% 10% 100°C 40°C 0-38°C

7400 System– 3.5- 87.5- 1.5- 37.5- 42- 230- 5.7- 675- 16.6- 2-4 5-9 24 — — 333402 333402 333402 — — 212°F <4502 104°F Yes 32-100°F

or

DTM 450 VOC Alkyd Enamel 6.0 150 2.5 62.5 43 390 9.6 690 17.0 5% 15% 641402 100°C 40°C 0-38°C

8400 System– 2.5- 62.5- 1-2 25- 39 265- 6.5- 625 15.3 2-4 4-6 24 — 633402 333402 333402 633402/ — — 212°F <450 104°F Yes 18-100°F

Industrial Food & Beverage Coating 4.5 112.5 50 530 13 up to 6% 5-10% 10-15% 6414 02 100°C 40°C -8-38°C

V8400 System– 3.5- 37.5- 1.5- 37.5- 47 250- 6.2- 750 18.5 2-4 4-8 24 — — 333402 333402 333402 — — 212°F <340 104°F Yes 32-100°F

Food & Beverage 340 VOC Alkyd 5.5 62.5 2.5 62.5 425 10.5 5-10% 10% 100°C 40°C 0-38°C

6100 System– 2.5- 62.5- 1.5- 37.5- 58 315- 7.7- 930 22.9 30 1 4 — — 333402 333402 333402 — — 212°F <340 78°F Yes 32-100°F

Shop Coat Primer NEW 4.5 111.25 2.5 62.5 525 12.9 min. 5% up tp 10% or 633402 25°C 0-38°C

Universal Acrylic Primer 3-6 75- 1-2 25- 34 350- 8.6- 545 13.4 35 1 1 — — — — Soap/ — — 212°F <100 180°F Yes 50-90°F

150 50 450 11.1 min. Water 100°C 82°C 10-32°C

5200 System DTM Acrylic 5-9 125- 2-3 50- 33- 150- 3.7- 530- 13- 1-2 2-4 1-3 — — Water Water Soap/ — — 200°F <250 >200°F Yes 50-100°F

225 75 38 260 6.4 610 15 Up to 6% Up to 12% Water 93°C 93°C 10-38°C

3100 System– 4-7 100- 1.5- 37.5- 36- 200- 4.9- 575- 14.1- ¼-1 1- 1 ½- — — — Water Soap/ — — 200°F <250 >212°F Yes 50-100°F

Speedy-Dry DTM Acrylic Enamel 175 2.5 62.5 39 350 8.6 625 15.4 1 ½ 2 5-10% Water 93°C 10 0°C 10-38°C

3700 System– 5-8 125- 2-3 50- 38- 170- 4.2- 609- 15.0- 1-2 2-4 1-3 — — Water Water Soap/ — — 200°F <250 212°F Yes 35-100°F

DTM Acrylic Enamel 200 75 40 275 6.7 641 15.8 6% 12% Water 93°C 100°C 2-38°C

9100 System DTM Epoxy Mastic 6.5- 162.5- 5-8 125- 78- 125- 3.1- 1250- 30.8- 6-8 6-12 16- — — — 160402 160402 1:1 2-41 300°F <340 110°F Yes 50-100°F

(with 9101402 Activator) 10.5 262.5 200 81 225 5.5 1300 32.0 72 10% 70°F 149°C 43°C 10-38°C

SC9100 System– 6.5- 162.5- 5.8 125- 75- 130- 3.2- 1214- 29.9- 8-10 10- 24 — — 333402 333402 333402 — 2-4 212°F <100 104°F Yes 32-100°F

100 VOC DTM Epoxy Mastic 10.0 250 200 80 215 5.3 1278 31.4 16 5-10% 10% 100°C 40°C 0-38°C

5300 System –Industrial Water-Based 4- 100- 1.5- 37.5- 38 200- 4.9- 600 14.8 ½-1 2-5 1-2 — — — Water Soap/ 7:1 6-8 300°F <250 132°F Yes 60-100°F

Epoxy w/5301604 Activator 6.5 162.5 2.5 62.5 350 8.6 10% Water 149°C 55°C 16-38°C

C9578 System – 10.5- 262.5- 8- 200- 75- 100- 2.5- 1203- 29.6- 3-4 18- 16- — — 160402 160402 160402 4:1 2 140°F <250 86°F No 50-100°F

Coal Tar Epoxy 13.5 337.5 10 250 77 130 3.2 1235 30.4 36 25 0-16% 0-16% MEK 80°F 60°C 48°C 10-30°C

W9200 System – 6.5- 162.5- 5-8 125- 73- 125- 3.1- 1170- 28.8- 3-5 8-12 24 — — 333402 333402 333402 — — 212°F <340 104°F Yes 32-100°F

Potable Water Coating 11.0 275 200 77 210 5.2 1235 30.4 5-10% 10% 100°C 40°C 0-38°C

HS9300 System Epoxy Primer 3.0- 75- 1.5- 37.5- 53 275- 6.5- 835 19.9 1-2 3-4 1 — — 333402 333402 333402 7:1 8-16 300°F <450 73°F Yes 60-100°F

5.0 125 2.5 62.5 475 11.3 5-10% 15-20% 149°C 41°C 16-38°C

9700 System – 250 VOC Acrylic Polyester 2-4 50- 1-2 25- 52.6- 360- 8.9- 845- 20.8- 2-4 3-6 16- — — — — Zylene or 4:1 3-4 300°F <250 20°F Yes 40-100°F

Urethane w/207243 Activator 100 50 62.8 860 21.2 1010 24.8 24 MEK 77°F 149°C -7°C 4-38°C

9400 System High-Gloss Polyester 3-5 75- 1-2 25- 37- 260- 6.4- 595- 14.6- 2-4 4-6 16 — — 190402 190402 190402 1:1 8-16 300°F <450 50°F Yes 32-100°F

Urethane w/9401402 Activator 125 50 41 560 13.8 660 16.2 15% 15% 149°C 10°C 0-38°C

9400 System High-Gloss Polyester 2-4 50- 1-2 25- 54- 370- 9.1- 866- 21.3- 2-4 6-8 16 — — 195402 195402 190402 1:1 2-4 300°F <450 50°F Yes 32-100°F

Urethane w/HS9401402 Activator 100 50 58 790 19.4 930 22.9 10-15% 15-20% 149°C 10°C 0-38°C

64 RUST-OLEUM INDUSTRIAL BRANDS PRODUCT GUIDE