Page 65 - RUST-OLEUM PRODUCT CATALOG (July 2014) 100-PAGES

P. 65

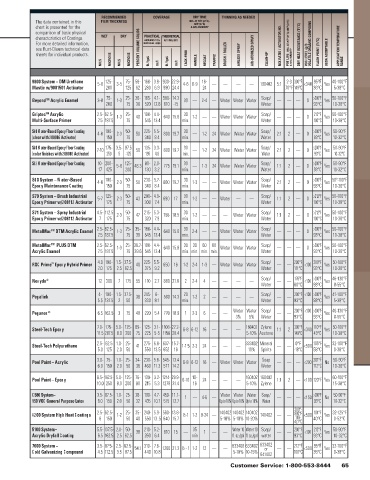

RECOMMENDED COVERAGE DRY TIME THINNING AS NEEDED

The data contained in this FILM THICKNESS HRS. AT 70˚F (21˚C)–

80˚F (27˚C)

chart is presented for the & 50% HUMIDITY

comparison of basic physical

characteristics of Coatings. WET DRY PRACTICAL THEORETICAL

ASSUMES 15%

AT 1 MIL DFT.

For more detailed information, MATERIAL LOSS POT LIFE HRS. AT 70˚F (21˚C)–80˚F (27˚C) DRY HEAT RESISTANCE (˚F/˚C) VOLATILE ORGANIC COMPOUND APPLICATION TEMPERATURE

see Rust-Oleum technical data PERCENT VOLUME SOLIDS AIR-ATOMIZED SPRAY MIX RATIO / ACTIVATOR NO.

sheets for individual products. TACK-FREE BRUSH / ROLLER AIRLESS SPRAY & 50% HUMIDITY VOC LEVEL (g/l) FLASH POINT (˚F/˚C) USDA ACCEPTABLE

MILS MICRONS MILS MICRONS ft. 2 /gal. m 2 /l ft. 2 /gal. m 2 /l HANDLE RECOAT TRAFFIC CLEAN-UP RANGE

9800 System – DM Urethane 5-8 125- 3-5 75- 58- 160- 3.9- 930- 22.9- 4-6 6-9 16- — — — — 190402 5:1 2-3 300°F <340 95°F Yes 40-100°F

Mastic w/9801501 Activator 200 125 62 280 6.9 990 24.4 24 70°F 149°C 36°C 5-38°C

Beyond Acrylic Enamel 3-8 75- 1-3 25- 36- 165- 4.1- 580- 14.3 30 — 2-4 — Water Water Water Soap/ — — — 0 >200°F Yes 50-100°F

TM

200 75 38 520 12.8 610 -15 Water 93°C 10-38°C

Griptec Acrylic 2.5- 62.5- 1-3 25- 40 180- 4.4- 640 15.8 30 1-2 — — Water Water Water Soap/ — — — 0 212°F Yes 50-100°F

TM

Multi-Surface Primer 7.5 187.5 75 545 13.4 min. Water 100°C 10-38°C

S40 Water-Based Epoxy Floor Coating 4-6 100- 2-3 50- 50 225- 5.5- 800 19.7 30 — 1-2 24 Water Water Water Soap/ 2:1 2 — 0 >200°F Yes 50-90°F

(clear with 208086 Activator) 150 75 340 8.4 min. Water 93°C 10-32°C

S40 Water-Based Epoxy Floor Coating 7-10 175- 3.5- 87.5 50 135- 3.3- 800 19.7 30 — 1-2 24 Water Water Water Soap/ 2:1 2 — 0 >200°F Yes 50-90°F

(color finishes with 208086 Activator) 250 5 -125 195 4.8 min. Water 93°C 10-32°C

S42 Water-Based Epoxy Floor Coating 10- 200- 5-8 125- 48.3 80- 2.0- 775 19.1 30 — 1-3 24 Water Water Water Soap/ 1:1 2 — 0 >200°F Yes 50-90°F

17 425 200 130 3.2 min. Water 93°C 10-32°C

S60 System – Water-Based 4-6 100- 2-3 50- 50 230- 5.7- 800 19.7 30 1-3 — — Water Water Water Soap/ 2:1 2 — 0 >200°F Yes 50°-100°F

Epoxy Maintenance Coating 150 75 340 8.4 min. Water 93°C 10-38°C

S70 System – Brush Industrial 5-7 125- 2-3 50- 43 200- 4.9- 690 17 30 1-2 — — Water — — Soap/ 1:1 2 — 0 >212°F Yes 50-100°F

Epoxy Primer w/208112 Activator 175 75 300 7.4 min. Water 100°C 10-38°C

S71 System – Spray Industrial 4.5- 112.5 2-3 50- 47 215- 5.3- 755 18.5 30 1-2 — — — Water Water Soap/ 1:1 2 — 0 >212°F Yes 50-100°F

Epoxy Primer w/208112 Activator 7 175 75 320 7.9 min. Water 100°C 10-38°C

MetalMax DTM Acrylic Enamel 2.5- 62.5- 1-3 25- 35- 180- 4.4- 640 15.8 30 2-4 — — Water Water Water Soap/ — — — 0 >200°F Yes 50-100°F

TM

7.5 187.5 75 39 545 13.4 min. Water 93°C 10-38°C

MetalMax PLUS DTM 2.5- 62.5- 1-3 25- 38.7- 180- 4.4- 640 15.8 30 30 60 60 Water Water Water Soap/ — — — 0 >200°F Yes 50-100°F

TM

Acrylic Enamel 7.5 187.5 75 39.6 545 13.4 min. min. min. min. Water 93°C 10-38°C

ROC Prime Epoxy Hybrid Primer 4.0 100- 1.5- 37.5- 40 225- 5.5- 650 16 1-2 2-4 1-3 — Water Water Water Soap/ — — 200°F <100 200°F Yes 50-100°F

™

7.0 175 2.5 62.5 375 9.2 Water 111°C 93°C 10-38°C

Noxyde ® 12 300 7 175 55 110 2.7 880 21.6 2 2-4 4 — — — — Soap/ — — 176°F <100 >200°F Yes 46-130°F

Water 80°C 93°C 8-55°C

Pegalink 4- 100- 1.5- 37.5- 36 245- 6- 580 14.3 20 1-2 2 — — — — Soap/ — — 200°F <100 >200°F Yes 41-100°F

5.5 137.5 2 50 330 8.1 min. Water 93°C 93°C 5-38°C

Peganox ® 6.5 162.5 3 75 48 220 5.4 770 18.9 1 2-3 6 — — Water Water Soap/ — — 200°F <100 >200°F Yes 46-130°F

3% 5% Water 93°C 93°C 8-55°C

Steel-Tech Epoxy 7.0- 175- 5.0- 125- 69- 125- 3.1- 1108- 27.2- 6-8 6-12 16 — — — 160402 Zylene 1:1 2 300°F <340 110°F Yes 50-100°F

11.5 287.5 8.0 200 75 225 5-5 1156 28.4 5-10% Acetone 149°C 43°C 10-38°C

Steel-Tech Polyurethane 2.5- 62.5 1.0- 25- 41 275- 6.8- 637- 15.7- 1-1.5 2-3 24 — — — 333402 Mineral — — 0°F <500 105°F Yes 32-100°F

5.0 125 2.0 50 550 13.5 652 16 10% Spirits -18°C 58°C 0-38°C

Pool Paint – Acrylic 3.0- 75- 1.0- 25- 34- 230- 5.6- 545- 13.4 6-8 6-12 16 — Water Water Water Soap — — — <200 201°F No 50-90°F

6.0 150 2.0 50 36 460 11.3 577 14.2 Water 112°C 10-38°C

Pool Paint – Epoxy 6.5- 162.5- 5.0- 125- 76- 130- 3.2- 1214- 29.9- 8-10 10- 24 — — — 160402 160402 1:1 2 — <100 120°F Yes 60-100°F

10.0 250 8.0 200 80 215 5.3 1279 31.4 16 5-10% Zylene 15-38°C

C580 System– 3.5- 87.5- 1.0- 25- 28- 190- 4.7- 450- 11.1- 1 — 4-6 — Water Water Water Soap/ — — — <150 >200°F No 50-90°F

150 VOC General Purpose Latex 6.0 150 2.0 50 32 435 10.7 515 12.7 Up to 10% Up to 10% Up to 10% Water 93°C 10-32°C

2.5- 62.5- 25- 35- 240- 5.9- 560- 13.8- 140402 140402 140402 300°- 104°F 32-125°F

4200 System High Heat Coatings 1-2 ½-1 1-2 8-24 — 140402 — — 800°F <500 40°C

Yes

149-

5-10% 5-10% 10-20%

6 150

50 40 550 13..5 640 15.7

427°C 0-52°C

5100 System– 5.5- 137.5- 2.0- 50- 38 210- 5.2- 610 15 — 35 1 — — Water 10 Water 10 Soap/ — — 200°F <100 212°F Yes 50-90°F

Acrylic Dryfall Coating 6.5 162.5 2.5 62.5 260 6.4 min fl. oz./gal fl. oz./gal water 93°C 93°C 10-32°C

7000 System – 3.5- 87.5- 2.5- 62.5- 54.1 310- 7.6- 1280 21.3 ½ - 1 1-2 12 — — 633402 633402 633402 — — 212°F <500 95°F Yes 32-100°F

or

Cold Galvanizing Compound 4.5 112.5 3.5 87.5 440 10.8 5-10% 10-15% 100°C 35°C 0-38°C

641402

Customer Service: 1-800-553-8444 65