Page 70 - RUST-OLEUM PRODUCT CATALOG (July 2014) 100-PAGES

P. 70

Concrete Prep, Patch & Repair

WATER-BASED TOPSIDE 100% SOLIDS TOPSIDE

VAPOR BARRIER VAPOR BARRIER

Water-Based TVB is a two component epoxy primer for TVB 100% Solids Topside Vapor Barrier is a two component, 100% solids

concrete floors. epoxy primer for concrete floors designed for floors with the most severe MVT

(Moisture Vapor Transmission) problems.

• Excellent adhesion to moisture laden slabs and can

be used to remedy concrete floors with high moisture • Excellent adhesion to moisture laden slabs and can be used to

levels before the application of the finish coating remedy concrete floors with high moisture levels before the

• Water-Based TVB is ph resistant and capable of holding back up application of the finish coating

to 12 lbs. of MVT (Moisture Vapor Transmission) with a two • ph resistant and capable of holding back up to 25 lbs. of MVT in a single application*

coat application • Use under coatings, wood flooring, carpeting or anywhere there is a MVT problem

• TVB Water-Based Topside Vapor Barrier can be applied to damp or * Must be applied over a properly prepared

green concrete shot blasted floor

This is a two-component system. Order base and activator separately. This is a two-component system. Order base and activator separately.

WATER-BASED 100% SOLIDS

277494 Part A Resin (59 fl oz in a one gallon container) 278269 Base (3 gallons in a 5 gallon pail)

278268 Part B Activator (81 fl oz in a two gallon container) 277500 Activator (81 fl oz in a two gallon container)

Water-Based Covers: 250 sq. ft./gal 100% Solids Covers: 80-100 sq. ft./gal

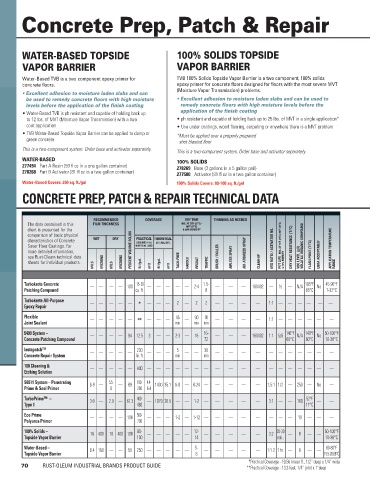

CONCRETE PREP, PATCH & REPAIR TECHNICAL DATA

RECOMMENDED COVERAGE DRY TIME THINNING AS NEEDED

The data contained in this FILM THICKNESS HRS. AT 70˚F (21˚C)–

80˚F (27˚C)

chart is presented for the & 50% HUMIDITY

comparison of basic physical

characteristics of Concrete WET DRY PRACTICAL THEORETICAL

ASSUMES 15%

AT 1 MIL DFT.

Saver Floor Coatings. For MATERIAL LOSS POT LIFE HRS. AT 70˚F (21˚C)–80˚F (27˚C) DRY HEAT RESISTANCE (˚F/˚C) VOLATILE ORGANIC COMPOUND APPLICATION TEMPERATURE

more detailed information, PERCENT VOLUME SOLIDS AIR-ATOMIZED SPRAY MIX RATIO / ACTIVATOR NO.

see Rust-Oleum technical data BRUSH / ROLLER AIRLESS SPRAY VOC LEVEL (g/l) FLASH POINT (˚F/˚C) USDA ACCEPTABLE 1

sheets for individual products. MICRONS MICRONS ft. 2 /gal. ft. 2 /gal. TACK-FREE HANDLE RECOAT TRAFFIC CLEAN-UP & 50% HUMIDITY

MILS MILS m 2 /l m 2 /l RANGE

Turbokrete Concrete — — — — 100 .15-.30 — — — — — 2-4 1.5- — — — 160402 — ½ — N/A 185°F No 45-90°F

Patching Compound cu. ft. 8 85°C 7-32°C

F

Turbokrete All-Purpose — — — — — — — — 2 — 2 2 — — — — 1:1 — — — — N— —o

Epoxy Repair . * 8 85°C 7-32°C

Flexible — — — — — — — — 45 — 90 90 — — — — 1:1 — — — — — —

Joint Sealant ** min min min

5499 System – — — — — 94 12.5 .3 — — 2-3 — 16 16- — — — 160402 1:1 5/6 140°F N/A 140°F No 50-100°F

Concrete Patching Compound 72 60°C 60°C 10-38°C

Instapatch™ — — — — — 230 — — — 5 — — 30 — — — — — — — — — — —

Concrete Repair System lin. ft. min min

108 Cleaning & — — — — — 400 — — — — — — — — — — — — — — — — — —

Etching Solution 72 60°C

S6511 System – Penetrating 6-9 — 5.5- — 89 180- 4.4- 1430 35.1 6-8 — 8-24 — — — — — 1.5:1 1/2 — 250 — No —

Prime & Seal Primer 8 260 6.4

TurboPrime™ – 3.0 — 2.0 — 67.3 400- — 1079 26.5 — — 1-2 — — — — — 3:1 — — 100 52°F — —

Type 1 460 11°C

Eco Prime — — — — 100 500- — — — 1-2 — 1-12 — — — — — — — — 10 — — —

Polyurea Primer 700

100% Solids – 16 400 16 400 100 80- — — — — — 12- — — — — — 3:2 20-30 — 0 — — 50-100°F

Topside Vapor Barrier 100 14 min.. 10-38°C

Water-Based – 6.4 160 — — 50 250 — — — — — 5- — — — — — 1:1.2 1 hr. — 0 — — 60-80°F

Topside Vapor Barrier 8 15.5-26.66°C

*Practical Coverage - 10.56 linear ft., 1/2” deep x 1/4” wide

70 RUST-OLEUM INDUSTRIAL BRANDS PRODUCT GUIDE **Practical Coverage - 13.3 feet, 1/4” joint x 1”deep