Page 20 - DP Digital Sample

P. 20

restorative section

CEMENTATION OF ZIRCONIA RESTORATIONS: A REVIEW

SACHIN DEEP SINGH

In recent decades, the increasing aesthetic needs in dentistry have tion of stabilizers, ceramics with remarkable properties like high

led to the progressive overcoming of metal-ceramic restorations. flexural strength and toughness, high hardness and chemical resist-

Today we have two main types of all ceramics: ance can be achieved.

1. Glass ceramics: these are the high strength ceramics which have Partially stabilized zirconia (PSZ) is widely studied and commer-

a glass silica phase to varying degrees. cially used. The ceramics consist mainly of cubic phase with tetrag-

2. Polycrystalline ceramics: Ultra high strength ceramics with no onal intra-granular zirconia precipitates generated during temper-

silica glass phase ing while cooling. The stabilizer utilized is stated as a prefix in the

name e.g. Mg- PSZ for MgO or Y-PSZ for Y2O3 as a stabilizer.

ZIRCONIA: POLYCRYSTALLINE CERAMIC Sintered material of yttria stabilized-tetragonal zirconia polycrys-

Zirconia is by far the most popular ceramic material being used for tals (Y-TZP) consists mainly (~98%) of metastable tetragonal phase

all ceramic restorations. Due to its high strength it finds many uses with 96-99.8% theoretical density. The quantity of utilized dopant is

ranging from single crowns to fixed partial dentures to complete mentioned in front of the abbreviation like 3Y-TZP when 3 mol%

arch implant supported frameworks. Its strength makes it possible Y2O3 is used.

to fabricate restorations to minimum thickness and achieve mini- Although the t-to-m transformation is detrimental in pure ZrO2,

mally invasive procedures but there are still issues about the cemen- it provides a decisive advantage in stabilized zirconia products. t- to-

tation of such restorations especially when they are considered m transformation in partially stabilized zirconia, results in an

against the glass ceramic restorations which can be easily bonded to increased strength and toughness of the material.

tooth structure. This leads to limitations of its applications when it Remarkable aspects resulting from transformation of the

comes to minimally invasive dentistry. metastable tetragonal phase to the monoclinic phase are (1) trans-

In this article we try to understand the structure of zirconia, its formation toughening and (2) increased crack resistance.

properties which make it such a unique material and various meth-

ods that have been developed to achieve predictable cementation of AGEING PROCESS: LOW TEMPERATURE DEGRADATION [LTD]

zirconia restorations. Zirconia is susceptible to aging or so called low temperature degra-

dation (LTD). During this ageing process the metastable tetragonal

SCIENCE phase converts by a slow transformation into the stable monoclinic

Zirconia is polymorph, existing in three different crystal structures phase, starting at the surface in the presence of water at relatively

depending on temperature and pressure. The crystal structures or low temperatures

phases are monoclinic (m), tetragonal (t) and cubic (c). At room This has a significant clinical implication, as rough unpolished

temperature, pure zirconia is present in the most stable phase, the zirconia surfaces created by using a bur/diamond point, in the pres-

monoclinic. As the temperature rises to about 1170°C, the mono- ence of saliva at mouth temperature can lead to LTD.

clinic phase transforms into the tetragonal phase, accompanied by To summarize zirconia is a polycrystalline material [no glass/sil-

shrinkage in volume of approximately 4-5%. The tetragonal phase ica phase], which due to phase changes have an inherent quality of

converts into the cubic phase at about 2370°C, with only minimal transformation toughening leading to high flexural strength and

changes in volume.

Cooling results in volume expansion, especially for the t-to-m

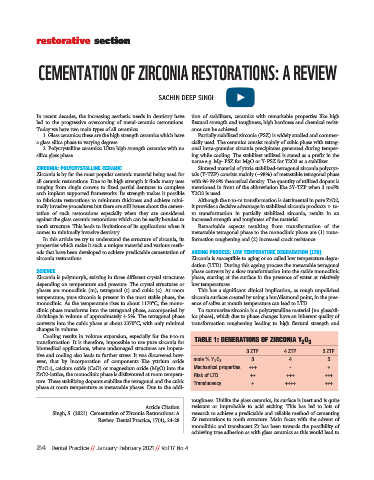

transformation. It is therefore, impossible to use pure zirconia for TABLE 1: GENERATIONS OF ZIRCONIA Y 2 O 3

biomedical applications, where undamaged structures are impera-

tive and cooling also leads to further stress. It was discovered how- 3 ZTP 4 ZTP 5 ZTP

O

ever, that by incorporation of components like yttrium oxide mole % Y 2 3 3 4 5

(Y O ), calcium oxide (CaO) or magnesium oxide (MgO) into the Mechanical properties +++ - +

2 3

ZrO2-lattice, the monoclinic phase is disfavoured at room tempera- Risk of LTD ++ +++ +++

ture. These stabilizing dopants stabilize the tetragonal and the cubic Translucency + ++++ +++

phase at room temperature as metastable phases. Due to the addi-

toughness. Unlike the glass ceramics, its surface is inert and is quite

Article Citation resistant or improbable to acid etching. This has led to lots of

Singh, S. (2021). Cementation of Zirconia Restorations: A research to achieve a predictable and reliable method of cementing

Review. Dental Practice, 17(4), 24-28 Zr restorations to tooth structure. Main focus with the advent of

monolithic and translucent Zr has been towards the possibility of

achieving true adhesion as with glass ceramics as this would lead to

24 Dental Practice // January-February 2021 // Vol 17 No 4