Page 23 - dust collection systems

P. 23

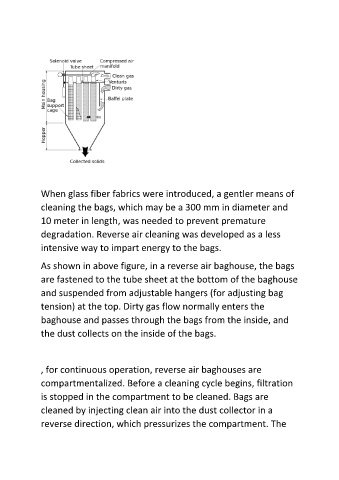

When glass fiber fabrics were introduced, a gentler means of

cleaning the bags, which may be a 300 mm in diameter and

10 meter in length, was needed to prevent premature

degradation. Reverse air cleaning was developed as a less

intensive way to impart energy to the bags.

As shown in above figure, in a reverse air baghouse, the bags

are fastened to the tube sheet at the bottom of the baghouse

and suspended from adjustable hangers (for adjusting bag

tension) at the top. Dirty gas flow normally enters the

baghouse and passes through the bags from the inside, and

the dust collects on the inside of the bags.

, for continuous operation, reverse air baghouses are

compartmentalized. Before a cleaning cycle begins, filtration

is stopped in the compartment to be cleaned. Bags are

cleaned by injecting clean air into the dust collector in a

reverse direction, which pressurizes the compartment. The