Page 3 - iotaflow

P. 3

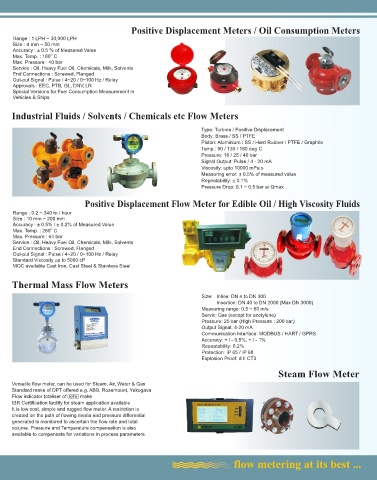

Positive Displacement Meters / Oil Consumption Meters

Range : 1 LPH ~ 30,000 LPH

Size : 4 mm ~ 50 mm

Accuracy : ± 0.5 % of Measured Value

O

Max. Temp. : 180 C

Max. Pressure : 40 bar

Service : Oil, Heavy Fuel Oil, Chemicals, Milk, Solvents

End Connections : Screwed, Flanged

Out-put Signal : Pulse / 4~20 / 0~100 Hz / Relay

Approvals : EEC, PTB, GL, DNV, LR

Special Versions for Fuel Consumption Measurement in

Vehicles & Ships

Industrial Fluids / Solvents / Chemicals etc Flow Meters

Type: Turbine / Positive Displacement

Body: Brass / SS / PTFE

Piston: Aluminium / SS / Hard Rubber / PTFE / Graphite

Temp.: 90 / 130 / 180 deg C

Pressure: 16 / 25 / 40 bar

Signal Output: Pulse / 4 - 20 mA

Viscosity: upto 10000 mPa.s

Measuring error: ± 0.5% of measured value

Repeatability: ± 0.1%

Pressure Drop: 0.1 ~ 0.5 bar at Qmax

Positive Displacement Flow Meter for Edible Oil / High Viscosity Fluids

Range : 0.2 ~ 340 m / hour

3

Size : 10 mm ~ 200 mm

Accuracy : ± 0.5% / ± 0.2% of Measured Value

O

Max. Temp. : 280 C

Max. Pressure : 64 bar

Service : Oil, Heavy Fuel Oil, Chemicals, Milk, Solvents

End Connections : Screwed, Flanged

Out-put Signal : Pulse / 4~20 / 0~100 Hz / Relay

Standard Viscosity up to 5000 cP

MOC available Cast Iron, Cast Steel & Stainless Steel

Thermal Mass Flow Meters

Size: Inline: DN 4 to DN 300

Insertion: DN 40 to DN 2000 (Max DN 3000)

Measuring range: 0.5 ~ 60 m/s

Servic: Gas (except for acetylene)

Pressure: 25 bar (High Pressure : 200 bar)

Output Signal: 4-20 mA

Communication Interface: MODBUS / HART / GPRS

Accuracy: + / - 0.5%, + / - 1%

Repeatability: 0.2%

Protection: IP 65 / IP 68

Explosion Proof: d II CT3

Steam Flow Meter

Versatile flow meter, can be used for Steam, Air, Water & Gas

Standard make of DPT offered e.g. ABB, Rosemount, Yukogava

Flow indicator totaliser of IOTA make

IBR Certification facility for steam application available

It is low cost, simple and rugged flow meter. A restriction is

created on the path of flowing media and pressure differential

generated is monitored to ascertain the flow rate and total

volume. Pressure and Temperature compensation is also

available to compensate for variations in process parameters.