Page 137 - Fundamental of Engineering Design

P. 137

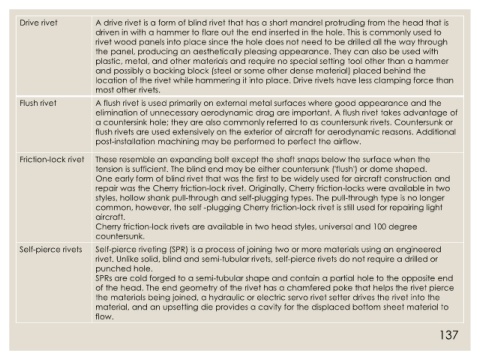

Drive rivet A drive rivet is a form of blind rivet that has a short mandrel protruding from the head that is

driven in with a hammer to flare out the end inserted in the hole. This is commonly used to

rivet wood panels into place since the hole does not need to be drilled all the way through

the panel, producing an aesthetically pleasing appearance. They can also be used with

plastic, metal, and other materials and require no special setting tool other than a hammer

and possibly a backing block (steel or some other dense material) placed behind the

location of the rivet while hammering it into place. Drive rivets have less clamping force than

most other rivets.

Flush rivet A flush rivet is used primarily on external metal surfaces where good appearance and the

elimination of unnecessary aerodynamic drag are important. A flush rivet takes advantage of

a countersink hole; they are also commonly referred to as countersunk rivets. Countersunk or

flush rivets are used extensively on the exterior of aircraft for aerodynamic reasons. Additional

post-installation machining may be performed to perfect the airflow.

Friction-lock rivet These resemble an expanding bolt except the shaft snaps below the surface when the

tension is sufficient. The blind end may be either countersunk ('flush') or dome shaped.

One early form of blind rivet that was the first to be widely used for aircraft construction and

repair was the Cherry friction-lock rivet. Originally, Cherry friction-locks were available in two

styles, hollow shank pull-through and self-plugging types. The pull-through type is no longer

common, however, the self -plugging Cherry friction-lock rivet is still used for repairing light

aircraft.

Cherry friction-lock rivets are available in two head styles, universal and 100 degree

countersunk.

Self-pierce rivets Self-pierce riveting (SPR) is a process of joining two or more materials using an engineered

rivet. Unlike solid, blind and semi-tubular rivets, self-pierce rivets do not require a drilled or

punched hole.

SPRs are cold forged to a semi-tubular shape and contain a partial hole to the opposite end

of the head. The end geometry of the rivet has a chamfered poke that helps the rivet pierce

the materials being joined, a hydraulic or electric servo rivet setter drives the rivet into the

material, and an upsetting die provides a cavity for the displaced bottom sheet material to

flow.

137