Page 136 - Fundamental of Engineering Design

P. 136

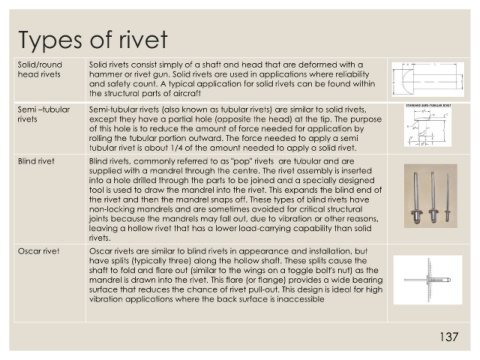

Types of rivet

Solid/round Solid rivets consist simply of a shaft and head that are deformed with a

head rivets hammer or rivet gun. Solid rivets are used in applications where reliability

and safety count. A typical application for solid rivets can be found within

the structural parts of aircraft

Semi –tubular Semi-tubular rivets (also known as tubular rivets) are similar to solid rivets,

rivets except they have a partial hole (opposite the head) at the tip. The purpose

of this hole is to reduce the amount of force needed for application by

rolling the tubular portion outward. The force needed to apply a semi

tubular rivet is about 1/4 of the amount needed to apply a solid rivet.

Blind rivet Blind rivets, commonly referred to as "pop" rivets are tubular and are

supplied with a mandrel through the centre. The rivet assembly is inserted

into a hole drilled through the parts to be joined and a specially designed

tool is used to draw the mandrel into the rivet. This expands the blind end of

the rivet and then the mandrel snaps off. These types of blind rivets have

non-locking mandrels and are sometimes avoided for critical structural

joints because the mandrels may fall out, due to vibration or other reasons,

leaving a hollow rivet that has a lower load-carrying capability than solid

rivets.

Oscar rivet Oscar rivets are similar to blind rivets in appearance and installation, but

have splits (typically three) along the hollow shaft. These splits cause the

shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the

mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing

surface that reduces the chance of rivet pull-out. This design is ideal for high

vibration applications where the back surface is inaccessible

137