Page 78 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 78

Good Environmental Practices

•Efficient Collection and Sorting of SLS Waste Powder

Proper systems are in place to ensure the effective collection and sorting of unused SLS powder, reducing contamination and

preserving material quality for recycling into filament.

•Performing Quality Control to Minimise Defective Filament Production

Rigorous testing is conducted to ensure the mechanical, thermal, and dimensional properties of the recycled filament meet

FDM printing standards. This minimises defective output and Waste during filament production.

•Collaborating with Industry Partners to Share Best Practices

ELH Tech works closely with partners, such as ITE College, and its network of Raise3D printer customers to promote the adoption

of recycled filament. Through workshops, demonstrations, and shared resources, ELH Tech fosters industry-wide awareness of

sustainable practices, helping to drive the transition toward a circular economy in additive manufacturing.

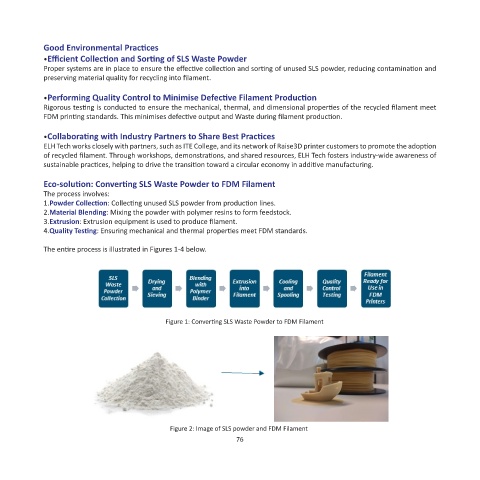

Eco-solution: Converting SLS Waste Powder to FDM Filament

The process involves:

1.Powder Collection: Collecting unused SLS powder from production lines.

2.Material Blending: Mixing the powder with polymer resins to form feedstock.

3.Extrusion: Extrusion equipment is used to produce filament.

4.Quality Testing: Ensuring mechanical and thermal properties meet FDM standards.

The entire process is illustrated in Figures 1-4 below.

Figure 1: Converting SLS Waste Powder to FDM Filament

Figure 2: Image of SLS powder and FDM Filament

76