Page 6 - QR CIMAR POWER TROWEL CPT-36

P. 6

CPT-36/F220/TEESIN/MAN/01/15 Compile by CJ

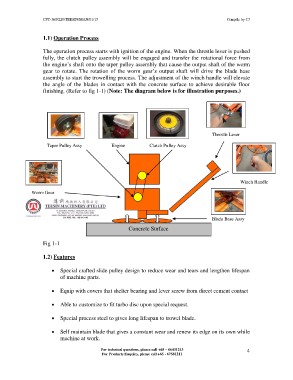

1.1) Operation Process

The operation process starts with ignition of the engine. When the throttle lever is pushed

fully, the clutch pulley assembly will be engaged and transfer the rotational force from

the engine’s shaft onto the taper pulley assembly that cause the output shaft of the worm

gear to rotate. The rotation of the worm gear’s output shaft will drive the blade base

assembly to start the trowelling process. The adjustment of the winch handle will elevate

the angle of the blades in contact with the concrete surface to achieve desirable floor

finishing. (Refer to fig 1-1) (Note: The diagram below is for illustration purposes.)

Throttle Lever

Taper Pulley Assy Engine Clutch Pulley Assy

Winch Handle

Worm Gear

Blade Base Assy

Concrete Surface

Fig 1-1

1.2) Features

Special crafted slide pulley design to reduce wear and tears and lengthen lifespan

of machine parts.

Equip with covers that shelter bearing and lever screw from direct cement contact

Able to customize to fit turbo disc upon special request.

Special process steel to gives long lifespan to trowel blade.

Self maintain blade that gives a constant wear and renew its edge on its own while

machine at work.

For technical questions, please call +65 – 66431213 4

For Products Enquiry, please call +65 - 67581211