Page 5 - GÜLNAR MACHINE CATALOG

P. 5

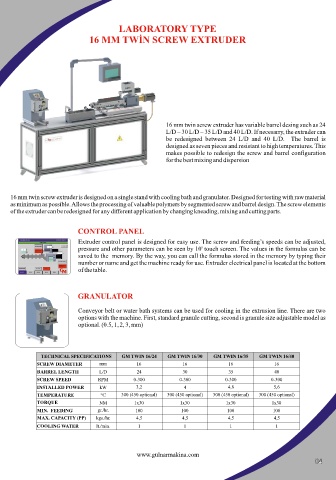

LABORATORY TYPE

16 MM TWİN SCREW EXTRUDER

16 mm twin screw extruder has variable barrel desing such as 24

L/D – 30 L/D – 35 L/D and 40 L/D. If necesarry, the extruder can

be redesigned between 24 L/D and 40 L/D. The barrel is

designed as seven pieces and resistant to high temperatures. This

makes possible to redesign the screw and barrel configuration

for the best mixing and dispersion

16 mm twin screw extruder is designed on a single stand with cooling bath and granulator. Designed for testing with raw material

as minimum as possible. Allows the processing of valuable polymers by segmented screw and barrel design. The screw elements

of the extruder can be redesigned for any different application by changing kneading, mixing and cutting parts.

CONTROL PANEL

Extruder control panel �s des�gned for easy use. The screw and feed�ng�s speeds can be adjusted,

pressure and other parameters can be seen by 10' touch screen. The values �n the formulas can be

saved to the memory. By the way, you can call the formulas stored �n the memory by typ�ng the�r

number or name and get the mach�ne ready for use. Extruder electr�cal panel �s located at the bottom

of the table.

GRANULATOR

Conveyor belt or water bath systems can be used for cooling in the extrusion line. There are two

options with the machine. First, standard granule cutting, second is granule size adjustable model as

optional. (0.5, 1, 2, 3, mm)

TECHNICAL SPECIFICATIONS GM TWIN 16/24 GM TWIN 16/30 GM TWIN 16/35 GM TWIN 16/40

SCREW DIAMETER mm 16 16 16 16

BARREL LENGTH L/D 24 30 35 40

SCREW SPEED RPM 0-300 0-300 0-300 0-300

INSTALLED POWER kW 3,2 4 4,8 5,6

TEMPERATURE °C 300 (450 optional) 300 (450 optional) 300 (450 optional) 300 (450 optional)

TORQUE NM 1x30 1x30 1x30 1x30

MIN. FEEDING gr./hr. 100 100 100 100

MAX. CAPACITY (PP) kgs./hr. 4,5 4,5 4,5 4,5

COOLING WATER lt./min. 1 1 1 1

www.gulnarmak�na.com

4

0 04