Page 17 - QT13442_STI001_CASE_DAEMO_ERKAT

P. 17

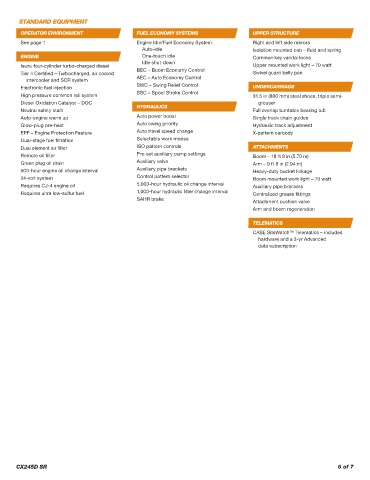

STANDARD EQUIPMENT

OPERATOR ENVIRONMENT FUEL ECONOMY SYSTEMS UPPER STRUCTURE

See page 1 Engine Idle/Fuel Economy System: Right and left side mirrors

Auto-idle Isolation mounted cab – fluid and spring

ENGINE One-touch idle Common key vandal locks

Idle shut-down

Isuzu four-cylinder turbo-charged diesel Upper mounted work light – 70 watt

Tier 4 Certified – Turbocharged, air cooled BEC – Boom Economy Control Swivel guard belly pan

intercooler and SCR system AEC – Auto Economy Control

SWC – Swing Relief Control

Electronic fuel injection UNDERCARRIAGE

High pressure common rail system SSC – Spool Stroke Control 31.5 in (800 mm) steel shoes, triple semi-

Diesel Oxidation Catalyst – DOC HYDRAULICS grouser

Neutral safety start Full overlap turntable bearing tub

Auto-engine warm up Auto power boost Single track chain guides

Glow-plug pre-heat Auto swing priority Hydraulic track adjustment

EPF – Engine Protection Feature Auto travel speed change X-pattern carbody

Dual-stage fuel filtration Selectable work modes

Dual element air filter ISO pattern controls ATTACHMENTS

Remote oil filter Pre-set auxiliary pump settings Boom – 18 ft 8 in (5.70 m)

Green plug oil drain Auxiliary valve Arm – 9 ft 8 in (2.94 m)

500-hour engine oil change interval Auxiliary pipe brackets Heavy-duty bucket linkage

24-volt system Control pattern selector Boom mounted work light – 70 watt

Requires CJ-4 engine oil 5,000-hour hydraulic oil change interval Auxiliary pipe brackets

Requires ultra low-sulfur fuel 1,000-hour hydraulic filter change interval Centralized grease fittings

SAHR brake

Attachment cushion valve

Arm and boom regeneration

TELEMATICS

CASE SiteWatch™ Telematics – includes

hardware and a 3-yr Advanced

data subscription

CX245D SR 6 of 7