Page 21 - Gi September2020

P. 21

FIGURE 1 BOILER RESEARCH FACILITY

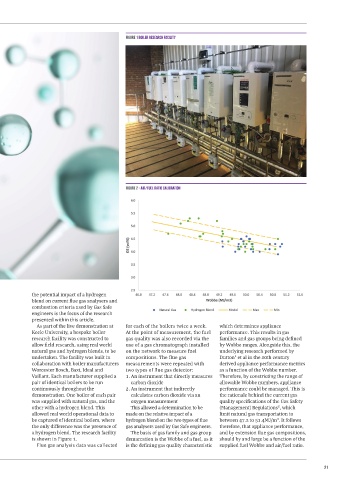

FIGURE 2 - AIR/FUEL RATIO CALIBRATION

the potential impact of a hydrogen

blend on current flue gas analysers and

combustion criteria used by Gas Safe

engineers is the focus of the research

presented within this article.

As part of the live demonstration at for each of the boilers twice a week. which determines appliance

Keele University, a bespoke boiler At the point of measurement, the fuel performance. This results in gas

research facility was constructed to gas quality was also recorded via the families and gas groups being defined

allow field research, using real world use of a gas chromatograph installed by Wobbe ranges. Alongside this, the

natural gas and hydrogen blends, to be on the network to measure fuel underlying research performed by

undertaken. The facility was built in compositions. The flue gas Dutton¹ et al in the 20th century

collaboration with boiler manufacturers measurements were repeated with derived appliance performance metrics

Worcester Bosch, Baxi, Ideal and two types of flue gas detector: as a function of the Wobbe number.

Vaillant. Each manufacturer supplied a 1. An instrument that directly measures Therefore, by constricting the range of

pair of identical boilers to be run carbon dioxide allowable Wobbe numbers, appliance

continuously throughout the 2. An instrument that indirectly performance could be managed. This is

demonstration. One boiler of each pair calculates carbon dioxide via an the rationale behind the current gas

was supplied with natural gas, and the oxygen measurement quality specifications of the Gas Safety

other with a hydrogen blend. This This allowed a determination to be (Management) Regulations², which

allowed real world operational data to made on the relative impact of a limit natural gas transportation to

be captured of identical boilers, where hydrogen blend on the two types of flue between 47.2 to 51.4MJ/m³. It follows

the only difference was the presence of gas analysers used by Gas Safe engineers. therefore, that appliance performance,

a hydrogen blend. The research facility The basis of gas family and gas group and by extension flue gas compositions,

is shown in Figure 1. demarcation is the Wobbe of a fuel, as it should by and large be a function of the

Flue gas analysis data was collected is the defining gas quality characteristic supplied fuel Wobbe and air/fuel ratio.

21

13/08/2020 09:24

ProgressiveEnergy.indd 2

ProgressiveEnergy.indd 2 13/08/2020 09:24