Page 37 - Gi flipbook_May 2019

P. 37

igem news – yppc

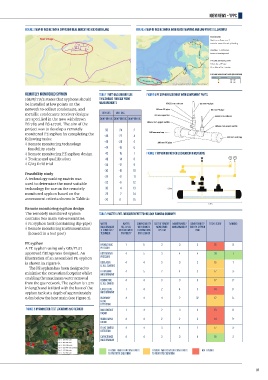

FIGURE 3 MAP OF GAS NETWORK SUPPLYING BEAL INDICATING HOLYGARTH LANE FIGURE 4 MAP OF GAS NETWORK WITH FLOOD MAPPING AND LOW POINTS (ELEVATION)

Remotely monitored syphon TABLE 1 WET GAS AND DRY GAS FIGURE 6 PE SYPHON ASSEMBLY WITH COMPONENT PARTS

IGEM/TD/3 states that syphons should THRESHOLDS FOR DEW POINT

be installed at low points on the MEASUREMENTS

network to collect condensate, and

metallic condensate receiver designs dry gas wet gas

are specified in the now withdrawn dew point Oc dew point Oc dew point Oc

BS 785 and BS 47726. The aim of the

project was to develop a remotely -50 -24 2

monitored PE syphon by completing the -48 -22 4

following tasks:

Remote monitoring technology -46 -20 5

feasibility study -44 -18 6

Remote monitoring PE syphon design -42 -16 7 FIGURE 7 SYPHON IMPACT ON EXCAVATION DIMENSIONS

Testing and qualification -40 -14 8

G/23 field trial -38 -12 9

-36 -10 10

Feasibility study

A technology ranking matrix was -34 -8 11

used to determine the most suitable -32 -6 12

technology for use on the remotely -30 -4 13

monitored syphon based on the -28 -2 14

assessment criteria shown in Table 2: -26 0 15

Remote monitoring syphon design

The remotely monitored syphon TABLE 2 WATER LEVEL MEASUREMENT TECHNOLOGY RANKING SUMMARY

contains two main sub-assemblies:

PE syphon tank (containing dip-pipe) water water compatability cost of remote maintenance/ compatability total score ranking

with remote

fill level

Remote monitoring instrumentation measurement measurement transmitting monitoring maintainability with pe syphon

technology/

tank

system

(housed in a test post) technique capability data logger

PE syphon hydrostatic 1 5 3 3 3 15 8

A PE syphon using only GIS/PL27 pressure

approved fittings was designed. An differential 4 5 3 4 4 20 1

illustration of an assembled PE syphon pressure

is shown in Figure 6. displacer 4 4 3 3 2 16 7

The PE syphon has been designed to level sensors

minimise the excavation footprint whilst ultrasonic 4 5 2 4 3 17 3=

measurement

enabling the maximum water removal

from the gas network. The syphon is 1.2m conductive 4 4 3 3 3 17 3=

level switch

in length and is fitted with the base of the laser level 1 4 2 4 3 14 9=

syphon tank at a depth of approximately measurement

0.6m below the host main (see Figure 7). buoyancy 4 4 4 2 32 17 3=

float

detection

FIGURE 5 HYGROMETER TEST LOCATIONS AND RESULTS non-contact 1 4 2 3 3 13 11

radar

guided wave 4 4 2 2 2 14 9=

radar

float switch 4 4 3 4 2 17 3=

detection

capacitance 4 4 3 3 4 18 2

measurement

feasible (with few challenges feasible (with several challenges not feasible

to prototpe creatiion) to prototpe creatiion)

37

IGEMNews_YPPC.indd 2 16/04/2019 19:01