Page 4 - Microsoft Word - IFWS2 Brochure.docx

P. 4

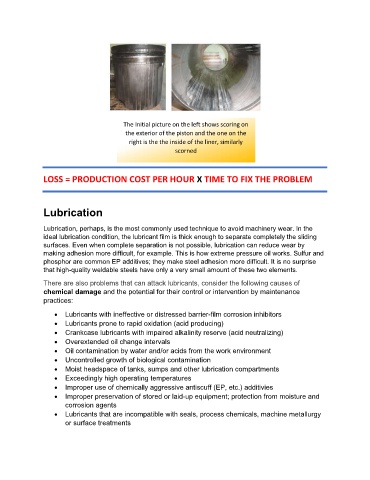

The Initial picture on the left shows scoring on

the exterior of the piston and the one on the

right is the the inside of the liner, similarly

scorned

LOSS = PRODUCTION COST PER HOUR X TIME TO FIX THE PROBLEM

Lubrication

Lubrication, perhaps, is the most commonly used technique to avoid machinery wear. In the

ideal lubrication condition, the lubricant film is thick enough to separate completely the sliding

surfaces. Even when complete separation is not possible, lubrication can reduce wear by

making adhesion more difficult, for example. This is how extreme pressure oil works. Sulfur and

phosphor are common EP additives; they make steel adhesion more difficult. It is no surprise

that high-quality weldable steels have only a very small amount of these two elements.

There are also problems that can attack lubricants, consider the following causes of

chemical damage and the potential for their control or intervention by maintenance

practices:

Lubricants with ineffective or distressed barrier-film corrosion inhibitors

Lubricants prone to rapid oxidation (acid producing)

Crankcase lubricants with impaired alkalinity reserve (acid neutralizing)

Overextended oil change intervals

Oil contamination by water and/or acids from the work environment

Uncontrolled growth of biological contamination

Moist headspace of tanks, sumps and other lubrication compartments

Exceedingly high operating temperatures

Improper use of chemically aggressive antiscuff (EP, etc.) additivies

Improper preservation of stored or laid-up equipment; protection from moisture and

corrosion agents

Lubricants that are incompatible with seals, process chemicals, machine metallurgy

or surface treatments