Page 5 - BROCHURE 1

P. 5

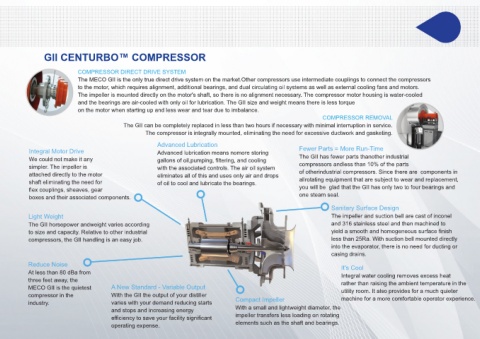

GII CENTURBO™ COMPRESSOR

COMPRESSOR DIRECT DRIVE SYSTEM

The MECO GII is the only true direct drive system on the market.Other compressors use intermediate couplings to connect the compressors

to the motor, which requires alignment, additional bearings, and dual circulating oil systems as well as external cooling fans and motors.

The impeller is mounted directly on the motor's shaft, so there is no alignment necessary. The compressor motor housing is water-cooled

and the bearings are air-cooled with only oil for lubrication. The GII size and weight means there is less torque

on the motor when starting up and less wear and tear due to imbalance.

COMPRESSOR REMOVAL

The GII can be completely replaced in less than two hours if necessary with minimal interruption in service.

The compressor is integrally mounted, eliminating the need for excessive ductwork and gasketing.

Advanced Lubrication

Integral Motor Drive Advanced lubrication means nomore storing Fewer Parts = More Run-Time

We could not make it any gallons of oil,pumping, filtering, and cooling The GII has fewer parts thanother industrial

simpler. The impeller is with the associated controls. The air oil system compressors andless than 10% of the parts

of otherindustrial compressors. Since there are components in

attached directly to the motor eliminates all of this and uses only air and drops

shaft eliminating the need for of oil to cool and lubricate the bearings. allrotating equipment that are subject to wear and replacement,

flex couplings, sheaves, gear you will be glad that the GII has only two to four bearings and

one steam seal.

boxes and their associated components.

Sanitary Surface Design

Light Weight The impeller and suction bell are cast of inconel

The GII horsepower andweight varies according and 316 stainless steel and then machined to

to size and capacity. Relative to other industrial yield a smooth and homogeneous surface finish

compressors, the GII handling is an easy job. less than 25Ra. With suction bell mounted directly

into the evaporator, there is no need for ducting or

casing drains.

Reduce Noise

It's Cool

At less than 80 dBa from

Integral water cooling removes excess heat

three feet away, the

rather than raising the ambient temperature in the

MECO GII is the quietest A New Standard - Variable Output

utility room. It also provides for a much quieter

compressor in the With the GII the output of your distiller

Compact Impeller machine for a more comfortable operator experience.

industry. varies with your demand reducing starts

With a small and lightweight diameter, the

and stops and increasing energy

impeller transfers less loading on rotating

efficiency to save your facility significant

elements such as the shaft and bearings.

operating expense.