Page 14 - Test Catalouge

P. 14

Back To Main Menu Turning Product Guidance

Cutting data, ISO Inserts

General ISO Turning Technical information Cutting data

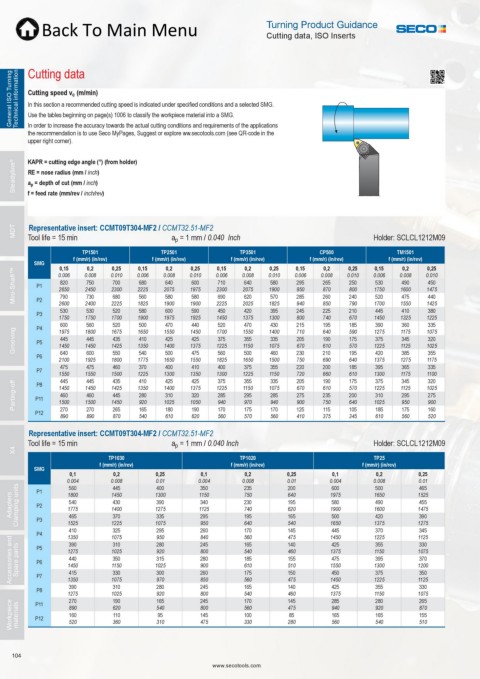

Cutting speed v c (m/min)

In this section a recommended cutting speed is indicated under specifi ed conditions and a selected SMG.

Use the tables beginning on page(s) 1006 to classify the workpiece material into a SMG.

In order to increase the accuracy towards the actual cutting conditions and requirements of the applications

the recommendation is to use Seco MyPages, Suggest or explore ww.secotools.com (see QR-code in the

upper right corner).

Steadyline ® KAPR = cutting edge angle (°) (from holder)

RE = nose radius (mm / inch)

a p = depth of cut (mm / inch)

f = feed rate (mm/rev / inch/rev)

MDT Tool life = 15 min a = 1 mm / 0.040 Inch Holder: SCLCL1212M09

Representative insert: CCMT09T304-MF2 / CCMT32.51-MF2

p

TP1501 TP2501 TP3501 CP500 TM1501

f (mm/r) (in/rev) f (mm/r) (in/rev) f (mm/r) (in/rev) f (mm/r) (in/rev) f (mm/r) (in/rev)

SMG 0,15 0,2 0,25 0,15 0,2 0,25 0,15 0,2 0,25 0,15 0,2 0,25 0,15 0,2 0,25

Mini-Shaft™ P1 0.006 0.008 0.010 0.006 0.008 0.010 0.006 0.008 0.010 0.006 0.008 0.010 0.006 0.008 0.010

600

250

450

680

295

820

265

640

490

640

530

710

700

580

750

2650

1600

2300

1750

2225

870

2450

800

950

1475

2075

1975

1900

2075

2300

580

690

680

475

520

440

620

240

730

285

580

560

790

570

260

P2

2600

530

450

395

245

600

520

225

590

580

210

420

530 2400 2225 1825 1900 1900 2225 2025 1825 940 850 790 1700 1550 1425

410

445

380

P3

1750 1750 1700 1900 1975 1925 1450 1375 1300 800 740 670 1450 1325 1225

500

360

600 1800 1675 1650 1550 1450 1700 1550 1400 215 195 185 1275 1175 1075

520

520

335

470

440

430

470

390

560

P4

Grooving P5 1450 1450 1425 1350 1400 1375 1225 1150 1075 205 190 175 1225 1125 1025

590

640

710

1975

335

410

345

425

355

375

320

425

445

445

375

435

610

670

570

P6 640 600 550 540 500 475 560 500 460 230 210 195 420 385 355

2100 1925 1800 1775 1650 1550 1825 1650 1500 750 690 640 1375 1275 1175

475 475 460 370 400 410 400 375 355 220 200 185 395 365 335

P7

1550 1550 1500 1225 1300 1350 1300 1225 1150 720 660 610 1300 1175 1100

P8 445 445 435 410 425 425 375 355 335 205 190 175 375 345 320

Parting-off P11 1450 1450 1425 1350 1400 1375 1225 1150 1075 670 610 570 1225 1125 1025

295

235

310

445

320

460

295

275

310

285

280

460

285

200

275

1050

970

1025

940

950

940

1025

900

920

1500

1500

1450

640

750

900

P12 270 270 265 165 180 190 170 175 170 125 115 105 185 175 160

890 890 870 540 610 620 560 570 560 410 375 345 610 560 520

Representative insert: CCMT09T304-MF2 / CCMT32.51-MF2

Tool life = 15 min a = 1 mm / 0.040 Inch Holder: SCLCL1212M09

p

X4

TP1030 TP1020 TP25

f (mm/r) (in/rev) f (mm/r) (in/rev) f (mm/r) (in/rev)

SMG

0,1 0,2 0,25 0,1 0,2 0,25 0,1 0,2 0,25

0.004 0.008 0.01 0.004 0.008 0.01 0.004 0.008 0.01

600

500

200

235

465

445

560

350

400

P1

Adapters Clamping units P2 1800 1450 1300 1150 750 640 1975 1650 1525

390

340

195

540

490

455

430

580

230

740

620

1475

1400

1125

1600

1900

1275

1775

500

390

370

295

165

335

465

420

195

P3

1525

325

170

445

260

345

295

145

410 1225 1075 950 640 540 1650 1375 1275

370

P4

Accessories and Spare parts P5 1275 1025 1025 800 540 460 1375 1150 1075

1350

560

840

1225

1075

1125

475

950

1450

310

425

390

245

355

280

330

165

140

920

475

185

315

155

440

395

350

280

370

P6

1150

1300

610

1550

1450

510

900

1200

300

260

175

330

150

450

350

415

375

P7

1350

390 1075 970 850 560 475 1450 1225 1125

280

355

425

140

310

245

165

330

P8

1275 1025 920 800 540 460 1375 1150 1075

Workpiece materials P12 890 620 540 800 560 475 940 920 870

265

190

270

165

285

145

170

245

280

P11

100

85

155

95

110

165

160

145

165

520

540

330

475

310

280

360

510

560

104

www.secotools.com