Page 32 - Training 2019

P. 32

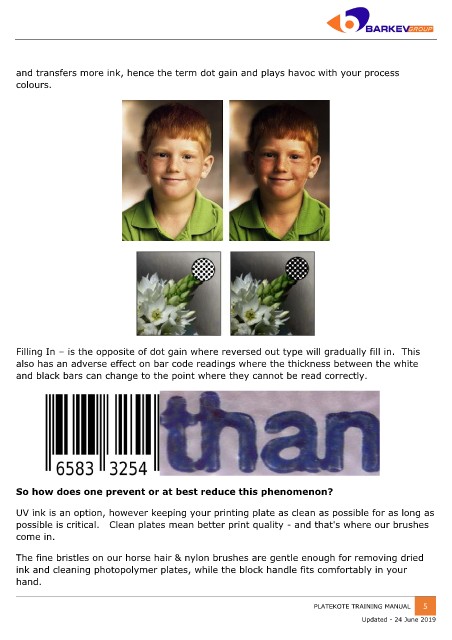

and transfers more ink, hence the term dot gain and plays havoc with your process

colours.

Filling In – is the opposite of dot gain where reversed out type will gradually fill in. This

also has an adverse effect on bar code readings where the thickness between the white

and black bars can change to the point where they cannot be read correctly.

So how does one prevent or at best reduce this phenomenon?

UV ink is an option, however keeping your printing plate as clean as possible for as long as

possible is critical. Clean plates mean better print quality - and that's where our brushes

come in.

The fine bristles on our horse hair & nylon brushes are gentle enough for removing dried

ink and cleaning photopolymer plates, while the block handle fits comfortably in your

hand.

PLATEKOTE TRAINING MANUAL 5

Updated - 24 June 2019