Page 2 - Barkev Product Catalogue

P. 2

GR

BARKEV PRINT CONSULTANTS

BARKEV COATINGS CC CK 1988/018503/23 GRAVURE, FLEXO, LITHO

TECHNICAL & SALES

HEAD OFFICE PH: 087 353 9740 / 031 020 0120 FAX: 031-701 3329

CAPE TOWN PH: 021- 558 3454 FAX: 021- 558 8683

GAUTENG PH:087 353 9642 FAX: 086 512 4091

www.barkev.co.za

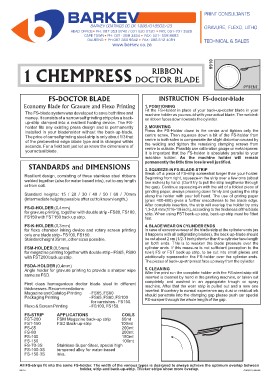

1 CHEMPRESS RIBBON 9910

DOCTOR BLADE

PATENT.

FS-DOCTOR BLADE INSTRUCTION FS-doctor-blade

Economy Blade for Gravure and Flexo Printing 1. POSITIONING

Fit the FS-Holder in place of your back-up-doctor blade in your

The FS-blade system was developed to save both time and machine holder as you would with your actual blade. The welded-

money. It consists of a narrow self grinding strip plus a back- on ribbon faces down towards the cylinder.

up-strip clamped into a resilient holding device. The FS-

holder fits any existing press design and is permanently 2. MOUNTING

installed in your bladeholder without the back-up-blade. Press the FS-Holder down in the centre and tighten only the

The price of our selfgrinding steel-strip is only about 1/3 that centre screw. Then squeeze down a bit of the FS-holder from

of the prebevelled edge blade type and is changed within centre to both sides to compensate the slight distortion caused by

seconds. For a field test just let us know the dimensions of the welding and tighten the remaining clamping screws from

your actual blade. centre to outside. Possibly use calibration gauge or metal spacer.

It is important that the FS-holder is absolutely parallel to your

STANDARDS and DIMENSIONS machine holder. As the machine holder will remain

permanently the little time loss is well justified.

Resilient design, consisting of three stainless steel ribbons

welded together (also for water based inks), cut to any length 3. SQUEEZE-IN FS-BLADE-STRIP

or from coil. Break off a piece of FS-strip somewhat longer than your holder.

Beginning from right, squeeze-in the strip over a few cms (about

Standard heights: 15 / 20 / 30 / 40 / 50 / 60 / 70mm two inches) by hand. (Don't try to pull the strip lengthwise through

(Intermediate heights possible after cut to known length.) the gap). Continue squeezing-in with the aid of a folded piece of

grinding paper, always pressing down firmly and guiding the strip

FS-D-HOLDER (0,4mm) along the holder with your left hand. The use of griding paper

for gravure printing, together with double strip - FS80, FS100, (grain 400-600) gives a further smoothness to the blade edge.

After complete insertion, the strip will overlap the holder by only

FS150 with FST150 back up strip. 1,3-2,8 mm (1/16-1/8 inch), according to the thickness of the blade

strip. When using FST back-up strip, back-up strip must be fitted

FS-K-HOLDER (0,3mm) first.

for flexo chamber inking device and rotary screen printing

4. BLADE WEAR ON CYLINDER ENDS

only one blade strip - FS100, FS150. In case of excessive wear of the blade strip at the cylinder ends (as

Standard height 35mm, other sizes possible. it happens with all selfgrinding blades), the back-up-blade should

be cut about 2 cm (1/2-1 inch) shorter than the cylinder face length

FSM-HOLDER (0,5mm) on both ends. This is to weaken the blade pressure over the

for magazine printing together with double strip - FS65, FS80 cylinder ends. If this measure is not sufficient (exception to the

rule!) FS or FST back-up strip, to be cut into small pieces and

with FST200 back up strip. additionally squeezed-in the FS-holder over the cylinder ends.

The pieces of back-up-strip must face up away from the cylinder.

FSDA-HOLDER (0,4mm)

Angle holder for gravure printing to provide a sharper wipe 5. CLEANING

After the print run the complete holder with the FS-steel-strip still

same as FSD. inserted is cleaned by hand in the printing machine, or taken out

completely and washed in an appropriate trough or spray

First class homogenious doctor blade steel in different machine. After that the worn strip is pulled out and a new one

inserted. If contrary to normal experience any dust or residual ink

thicknesses. Recommendations: should penetrate into the clamping gap please push our special

FS-scraper through the whole length of the gap.

Magazine and Catalog-Printing - FS65, FS80

Packaging Printing - FS65, FS80, FS100

for varnishes - FS150.

Flexo & Screen Printing - FS100, FS150.

FS-STRIP APPLICATIONS COILS

FST-200

FST-150 FSM Magazine back-up strip 60mt

FS-65

FS-80 FSD Back-up-strip 100mt

FS-100

FS-150 200mt

FS-70-3S

FS-100-3S 200mt

FS-150-3S

150mt

100mt

Stainless-Super-Steel, special high

tempered alloy for water-based

inks.

All FS-strips fit into the same FS-holder. The width of the various types is designed to always achieve the optimum overlap between

896-14 holder, strip and back-up-strip. Thicker strips show more overlap. AYM (031) 7085002