Page 3 - Barkev Product Catalogue

P. 3

GR

BARKEV PRINT CONSULTANTS

BARKEV COATINGS CC CK 1988/018503/23 GRAVURE, FLEXO, LITHO

TECHNICAL & SALES

HEAD OFFICE PH: 087 353 9740 / 031 020 0120 FAX: 031-701 3329

CAPE TOWN PH: 021- 558 3454 FAX: 021- 558 8683

GAUTENG PH:087 353 9642 FAX: 086 512 4091

www.barkev.co.za

2 METAL LAMELLA DOCTOR BLADES

9910

- Made from Swedish tempered steel. 55-70

- Ideal for packaging, magazine, flexographic, tampon, textile applications. degrees

- Ideal for direct gravure, chamber, reverse angle systems.

- Suitable with all inks and coating systems.

- Reduced pressure required.

- Constant blade contact despite blade wear.

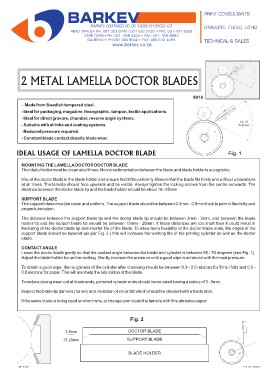

IDEAL USAGE OF LAMELLA DOCTOR BLADE Fig. 1

MOUNTING THE LAMELLA DOCTOR DOCTOR BLADE

The blade holder must be clean at all times. No ink sedimentation between the blade and blade holder is acceptable.

Mount the doctor blade in the blade holder and ensure that it fits uniformly. Ensure that the blade fits firmly and without undulations

at all times. The lamella should face upwards and be visible. Always tighten the locking screws from the centre outwards. The

distance between the doctor blade tip and the blade holder should be about 18 - 25mm.

SUPPORT BLADE

The support blade must be clean and uniform. The support blade should be between 0,3mm - 0,8mm thick to permit flexibility and

proper lubrication.

The distance between the support blade tip and the doctor blade tip should be between 3mm - 5mm, and between the blade

holder tip and the support blade tip should be between 15mm - 20mm. If these distances are too short then it could result in

fracturing of the doctor blade tip and shorter life of the blade. To allow more flexibility at the doctor blade ends, the edges of the

support blade should be tapered (as per Fig. 2.) this will increase the working life of the printing cylinder as well as the doctor

blade.

CONTACT ANGLE

Lower the doctor blade gently so that the contact angle between the blade and cylinder is between 55 - 70 degrees (see Fig. 1).

Adjust the blade holder for uniforn setting. Gently increase the pressure until a good wipe is achieved with the least pressure.

To obtain a good wipe, the roughness of the cylinder after chroming should be between 0,3 - 0,5 microns for films / foils and 0,5 -

0,8 microns for paper. This will also help the lubrication of the blade.

To reduce strong wear-out at blade ends, polished cylinder ends should be rounded having a radius of 3 - 5mm.

Inspect the blade tip (lamella) for any accumulation of ink or dirt which should be cleaned with a blade stick.

If the same blade is being used on short runs, at change over clean the lamella with fine abrasive paper.

3-5mm Fig. 2

15-20mm

DOCTOR BLADE

SUPPORT BLADE

BLADE HOLDER

896-16(134) AYM (031) 7085002