Page 47 - Barkev Product Catalogue

P. 47

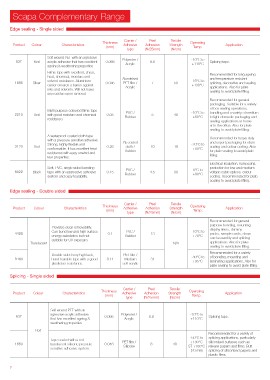

Scapa Complementary Range

Edge sealing - Single sided

Product Colour Characteristics Thickness Carrier / Peel Tensile Operating Application

637 (mm) Adhesive Adhesion Strength Temp.

1695 (N/25mm) (N/cm)

type

8.8

Red Self wound PET with an agressive 0.066 Polyester / - -10°C to Splicing tape.

Silver acrylic adhesive that has excellent 0.045 Acrylic 7 +110°C

ageing & weathering properties

Aluminised Recommended for long ageing

Filmic tape with excellent, shear, PET film /

heat, chemical, moisture and 50 -15°C to and temperature resistant

solvent resistance. Aluminium Acrylic +130°C splicing, decorative and sealing

carrier ensures a barrier against applications. Also for plate

inks and solvents. Will not leave

any residue upon removal. sealing to avoid plate lifting.

Recommended for general

packaging. Suitable for a variety

Multi-purpose coloured filmic tape of box sealing operations,

Red with good moisture and chemical

2210 0.05 PVC / 5 48 -10°C to bundling and a variety of medium

resistance. Rubber +60°C to light domestic packaging and

sealing applications at home

or in the office. Also for plate

sealing to avoid plate lifting.

A waterproof coated cloth tape Recommended for heavy duty

with a pressure sensitive adhesive. PE coated and export packaging for drum

cloth / sealing and colour coding. Also

3120 Red Strong, highly flexible and 0.26 Rubber 10 18 -20°C to for plate sealing to avoid plate

6022 conformable. It has excellent heat 0.15 4.5 +80°C

PVC /

resistance with easy unwind and Rubber lifting.

tear properties.

Electrical insulation, hamessing,

Black Soft, PVC, single sided bonding 30 0°C to protection for low and medium

tape with an aggressive adhesive +90°C voltage cable splices, colour

system and easy tearability. coding. Recommended for plate

sealing to avoid plate lifting.

Edge sealing - Double sided

Product Colour Characteristics Thickness Carrier / Peel Tensile Operating Application

(mm) Adhesive Adhesion Strength Temp.

(N/25mm) (N/cm)

type

N/A

4400 Provides clean removability. 0.1 PVC / 13 -10°C to Recommended for general

Can bond low and high surface Rubber 31 +70°C purpose bonding, mounting

energy substrates but not display items, dummy

Translucent suitable for UV exposure. -40°C to packs, sample cards, show

+95°C card assembly and splicing

D160 Double-sided very high tack, PET film / applications. Also for plate

sealing to avoid plate lifting.

hand tearable tape with a good 0.11 Medium

Recommended for a variety

plasticiser resistance. soft acrylic of bonding, mounting and

laminating applications. Also for

plate sealing to avoid plate lifting.

Splicing - Single sided

Product Colour Characteristics Thickness Carrier / Peel Tensile Operating Application

(mm) Adhesive Adhesion Strength Temp.

(N/25mm) (N/cm)

type

637 Self wound PET with an 0.066 Polyester / 8.8 - -10°C to Splicing tape.

1650 agressive acrylic adhesive Acrylic 8 +110°C

that has excellent ageing &

weathering properties Recommended for a variety of

Red -50°C to splicing applications, particularly

Tape coated with a red 0.048 PET film / 40 +130°C siliconised surfaces such as

translucent silicone pressure Silicone ST +180°C release papers and films. Butt

sensitive adhesive system.

(20 min) splicing of siliconised papers and

plastic films.

7