Page 134 - Flipbook_SolidDesignSoutheast2020

P. 134

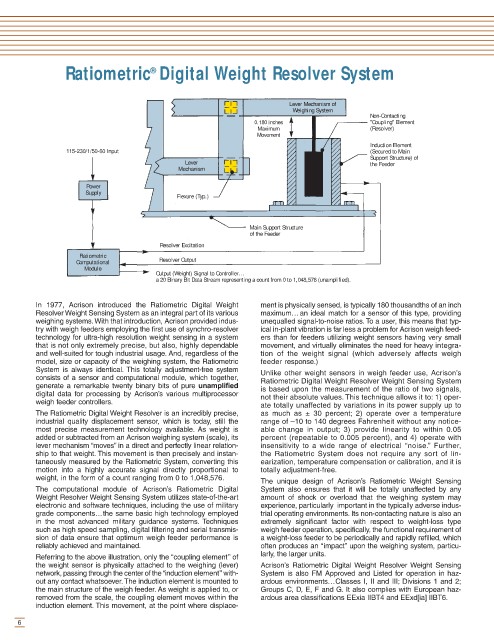

Ratiometric Digital Weight Resolver System

®

Lever Mechanism of

Weighing System

Non-Contacting

0.180 inches "Coupling" Element

Maximum (Resolver)

Movement

Induction Element

115-230/1/50-60 Input (Secured to Main

Support Structure) of

Lever the Feeder

Mechanism

Power

Supply

Flexure (Typ.)

Main Support Structure

of the Feeder

Resolver Excitation

Ratiometric

Computational Resolver Output

Module

Output (Weight) Signal to Controller…

a 20 Binary Bit Data Stream representing a count from 0 to 1,048,576 (unamplified).

In 1977, Acrison introduced the Ratiometric Digital Weight ment is physically sensed, is typically 180 thousandths of an inch

Resolver Weight Sensing System as an integral part of its various maximum… an ideal match for a sensor of this type, providing

weighing systems.With that introduction, Acrison provided indus- unequalled signal-to-noise ratios. To a user, this means that typ-

try with weigh feeders employing the first use of synchro-resolver ical in-plant vibration is far less a problem for Acrison weigh feed-

technology for ultra-high resolution weight sensing in a system ers than for feeders utilizing weight sensors having very small

that is not only extremely precise, but also, highly dependable movement, and virtually eliminates the need for heavy integra-

and well-suited for tough industrial usage. And, regardless of the tion of the weight signal (which adversely affects weigh

model, size or capacity of the weighing system, the Ratiometric feeder response.)

System is always identical. This totally adjustment-free system Unlike other weight sensors in weigh feeder use, Acrison’s

consists of a sensor and computational module, which together, Ratiometric Digital Weight Resolver Weight Sensing System

generate a remarkable twenty binary bits of pure unamplified is based upon the measurement of the ratio of two signals,

digital data for processing by Acrison’s various multiprocessor not their absolute values. This technique allows it to: 1) oper-

weigh feeder controllers.

ate totally unaffected by variations in its power supply up to

The Ratiometric Digital Weight Resolver is an incredibly precise, as much as ± 30 percent; 2) operate over a temperature

industrial quality displacement sensor, which is today, still the range of –10 to 140 degrees Fahrenheit without any notice-

most precise measurement technology available. As weight is able change in output; 3) provide linearity to within 0.05

added or subtracted from an Acrison weighing system (scale), its percent (repeatable to 0.005 percent), and 4) operate with

lever mechanism “moves” in a direct and perfectly linear relation- insensitivity to a wide range of electrical “noise.” Further,

ship to that weight. This movement is then precisely and instan- the Ratiometric System does not require any sort of lin-

taneously measured by the Ratiometric System, converting this earization, temperature compensation or calibration, and it is

motion into a highly accurate signal directly proportional to totally adjustment-free.

weight, in the form of a count ranging from 0 to 1,048,576.

The unique design of Acrison’s Ratiometric Weight Sensing

The computational module of Acrison’s Ratiometric Digital System also ensures that it will be totally unaffected by any

Weight Resolver Weight Sensing System utilizes state-of-the-art amount of shock or overload that the weighing system may

electronic and software techniques, including the use of military experience, particularly important in the typically adverse indus-

grade components…the same basic high technology employed trial operating environments. Its non-contacting nature is also an

in the most advanced military guidance systems. Techniques extremely significant factor with respect to weight-loss type

such as high speed sampling, digital filtering and serial transmis- weigh feeder operation, specifically, the functional requirement of

sion of data ensure that optimum weigh feeder performance is a weight-loss feeder to be periodically and rapidly refilled, which

reliably achieved and maintained. often produces an “impact” upon the weighing system, particu-

larly, the larger units.

Referring to the above illustration, only the “coupling element” of

the weight sensor is physically attached to the weighing (lever) Acrison’s Ratiometric Digital Weight Resolver Weight Sensing

network, passing through the center of the “induction element” with- System is also FM Approved and Listed for operation in haz-

out any contact whatsoever.The induction element is mounted to ardous environments…Classes I, II and III; Divisions 1 and 2;

the main structure of the weigh feeder. As weight is applied to, or Groups C, D, E, F and G. It also complies with European haz-

removed from the scale, the coupling element moves within the ardous area classifications EExia IIBT4 and EExd[ia] IIBT6.

induction element. This movement, at the point where displace-

6