Page 139 - Flipbook_SolidDesignSoutheast2020

P. 139

Models203and 203B Weigh Feeders

Operation

As the Prefeeder discharges product onto the scale- • Output Capacities:

mounted synchronous speed Weigh Belt or Weigh - For Model 203 Weigh Belt Feeders, the total output

Auger, a proportional-to-weight signal is generated by capacity ranges from 60 to 48,000 pounds per hour.

the Ratiometric Digital Weight Resolver, which is then - For Model 203B Weigh Auger Feeders, the total output

compared to the selected feed rate. Any difference capacity ranges from 120 to 136,000 pounds per hour.

between these signals results in correction to the feed

rate of the Prefeeder, altering its output accordingly — Note: Output capacities are based on a product weighing

so that the actual output (weighed) feed rate precisely 40 pounds per cubic foot.

matches the selected feed rate. The Prefeeder is driven • Feed Range: The feed range for both the Models 203

by a variable speed drive.

and 203B Weigh Feeders is 20:1 from the maximum

Typically, the accuracy generated by the prefeeder ranges designed output capacity of the particular feeder model.

between ± 1 to 3 percent or better (error) for the majority • Ambient Temperature Operating Range: All Acrison

of ingredients. And, because of this already established weigh feeders are designed to operate within an ambient

preliminary accuracy, little correction in the feed rate temperature range of –10 to 140 degrees Fahrenheit.

output of the Prefeeder is usually required to achieve

highest levels of weigh feeder performance. The result is • Controls: Please see page 7.

a uniform and extremely accurate flow of material.

• Electrical: Power requirements are either 115/1/60 or

230/1/60 depending upon the feeder model and size.

Features All motors are totally enclosed.

• Metering Accuracy: Metering accuracy is typically

±0.25 to 1 percent or better (error) at two sigma,

based on a given number of consecutive one minute As an indication of Acrison’s confidence level in this

weighments.

equipment, the entire weighing mechanism of the weigh

• Weighing System Specifications: See page 4. feeder , including its Ratiometric Digital Weight Resolver,

is guaranteed for five years from the date of shipment.

• Versatility: The appropriate model Prefeeder ensures

dependable metering of a wide range of dry solid

ingredients regardless of handling characteristics.

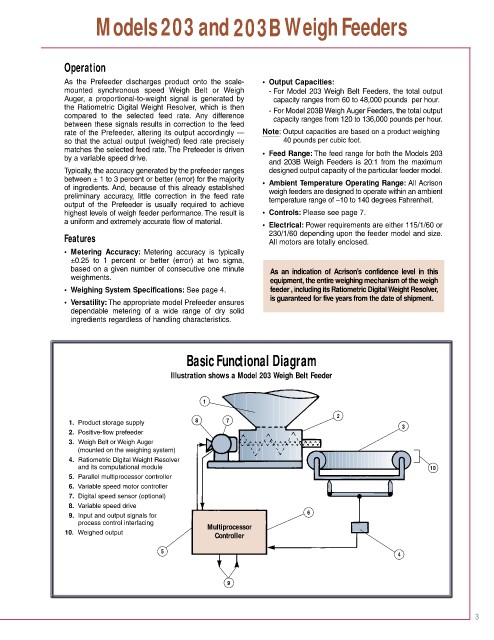

Basic Functional Diagram

Illustration shows a Model 203 Weigh Belt Feeder

1

2

1. Product storage supply 8 7

3

2. Positive-flow prefeeder

3. Weigh Belt or Weigh Auger

(mounted on the weighing system)

4. Ratiometric Digital Weight Resolver

and its computational module 10

5. Parallel multiprocessor controller

6. Variable speed motor controller

7. Digital speed sensor (optional)

8. Variable speed drive

6

9. Input and output signals for

process control interfacing

Multiprocessor

10. Weighed output

Controller

5

4

9

3