Page 148 - Flipbook_SolidDesignSoutheast2020

P. 148

• Selectable auto stop of feeder on hopper (or tank) empty • The SBC-2000 CM has two electrically isolated, general

or refill time-out (LIW feeders). purpose, RS- 422/485, user-configurable channels, typi-

• Auto pacing during refill (LIW feeders). cally for host communications. The SBC-2000 DSP and

DSP/C have one channel each, suitable for connecting

• Configure using Web browser.

devices up to 4,000 feet away. Protocols available for use

• Language selection: English, German, French, Spanish. on these channels include:

• Alarm Log (SBC-2000 DSP/C and SBC-2000 MFC only).

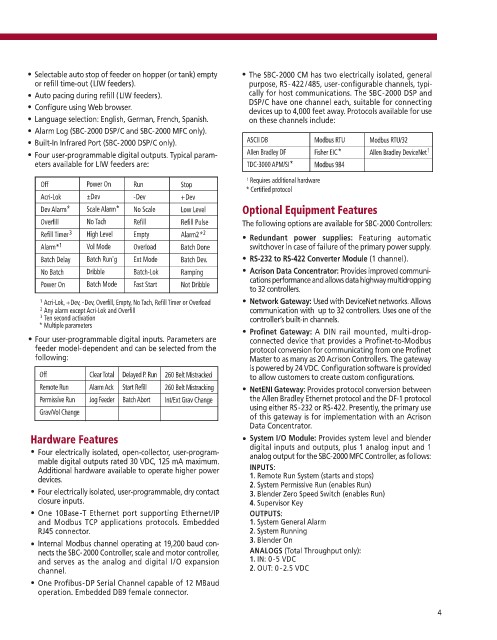

• Built-In Infrared Port (SBC-2000 DSP/C only). ASCII DB Modbus RTU Modbus RTU/32

• Four user-programmable digital outputs. Typical param- Allen Bradley DF Fisher EIC* Allen Bradley DeviceNet 1

eters available for LIW feeders are: TDC-3000 APM/SI* Modbus 984

1 Requires additional hardware

Off Power On Run Stop

* Certified protocol

Acri-Lok ±Dev -Dev +Dev

Dev Alarm* Scale Alarm* No Scale Low Level Optional Equipment Features

Overfill No Tach Refill Refill Pulse The following options are available for SBC-2000 Controllers:

Refill Timer 3 High Level Empty Alarm2* 2 • Redundant power supplies: Featuring automatic

Alarm* 1 Vol Mode Overload Batch Done switchover in case of failure of the primary power supply.

Batch Delay Batch Run'g Ext Mode Batch Dev. • RS-232 to RS-422 Converter Module (1 channel).

No Batch Dribble Batch-Lok Ramping • Acrison Data Concentrator: Provides improved communi-

cations performance and allows data highway multidropping

Power On Batch Mode Fast Start Not Dribble

to 32 controllers.

1 Acri-Lok, +Dev, -Dev, Overfill, Empty, No Tach, Refill Timer or Overload • Network Gateway: Used with DeviceNet networks. Allows

2 Any alarm except Acri-Lok and Overfill communication with up to 32 controllers. Uses one of the

3 Ten second activation controller’s built-in channels.

* Multiple parameters

• Profinet Gateway: A DIN rail mounted, multi-drop-

• Four user-programmable digital inputs. Parameters are connected device that provides a Profinet-to-Modbus

feeder model-dependent and can be selected from the protocol conversion for communicating from one Profinet

following: Master to as many as 20 Acrison Controllers. The gateway

is powered by 24 VDC. Configuration software is provided

Off Clear Total Delayed P. Run 260 Belt Mistracked to allow customers to create custom configurations.

Remote Run Alarm Ack Start Refill 260 Belt Mistracking • NetENI Gateway: Provides protocol conversion between

Permissive Run Jog Feeder Batch Abort Int/Ext Grav Change the Allen Bradley Ethernet protocol and the DF-1 protocol

using either RS-232 or RS-422. Presently, the primary use

Grav/Vol Change

of this gateway is for implementation with an Acrison

Data Concentrator.

Hardware Features • System I/O Module: Provides system level and blender

digital inputs and outputs, plus 1 analog input and 1

• Four electrically isolated, open-collector, user-program- analog output for the SBC-2000 MFC Controller, as follows:

mable digital outputs rated 30 VDC, 125 mA maximum.

Additional hardware available to operate higher power INPUTS:

devices. 1. Remote Run System (starts and stops)

2. System Permissive Run (enables Run)

• Four electrically isolated, user-programmable, dry contact 3. Blender Zero Speed Switch (enables Run)

closure inputs. 4. Supervisor Key

• One 10Base-T Ethernet port supporting Ethernet/IP OUTPUTS:

and Modbus TCP applications protocols. Embedded 1. System General Alarm

RJ45 connector. 2. System Running

3. Blender On

• Internal Modbus channel operating at 19,200 baud con-

nects the SBC-2000 Controller, scale and motor controller, ANALOGS (Total Throughput only):

and serves as the analog and digital I/O expansion 1. IN: 0-5 VDC

channel. 2. OUT: 0-2.5 VDC

• One Profibus-DP Serial Channel capable of 12 MBaud

operation. Embedded DB9 female connector.

4