Page 242 - Flipbook_SolidDesignSoutheast2020

P. 242

Acrison ®

Bulk Bag Unloader

Model 821

For Dry Solid Materials

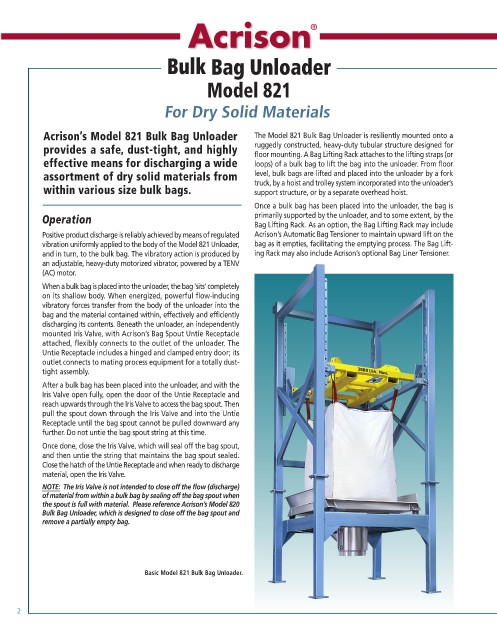

Acrison’s Model 821 Bulk Bag Unloader The Model 821 Bulk Bag Unloader is resiliently mounted onto a

provides a safe, dust-tight, and highly ruggedly constructed, heavy-duty tubular structure designed for

floor mounting. A Bag Lifting Rack attaches to the lifting straps (or

effective means for discharging a wide loops) of a bulk bag to lift the bag into the unloader. From floor

assortment of dry solid materials from level, bulk bags are lifted and placed into the unloader by a fork

truck, by a hoist and trolley system incorporated into the unloader’s

within various size bulk bags. support structure, or by a separate overhead hoist.

Once a bulk bag has been placed into the unloader, the bag is

Operation primarily supported by the unloader, and to some extent, by the

Bag Lifting Rack. As an option, the Bag Lifting Rack may include

Positive product discharge is reliably achieved by means of regulated Acrison’s Automatic Bag Tensioner to maintain upward lift on the

vibration uniformly applied to the body of the Model 821 Unloader, bag as it empties, facilitating the emptying process. The Bag Lift-

and in turn, to the bulk bag. The vibratory action is produced by ing Rack may also include Acrison’s optional Bag Liner Tensioner.

an adjustable, heavy-duty motorized vibrator, powered by a TENV

(AC) motor.

When a bulk bag is placed into the unloader, the bag ‘sits’ completely

on its shallow body. When energized, powerful flow-inducing

vibratory forces transfer from the body of the unloader into the

bag and the material contained within, effectively and efficiently

discharging its contents. Beneath the unloader, an independently

mounted Iris Valve, with Acrison’s Bag Spout Untie Receptacle

attached, flexibly connects to the outlet of the unloader. The

Untie Receptacle includes a hinged and clamped entry door; its

outlet connects to mating process equipment for a totally dust-

tight assembly.

After a bulk bag has been placed into the unloader, and with the

Iris Valve open fully, open the door of the Untie Receptacle and

reach upwards through the Iris Valve to access the bag spout. Then

pull the spout down through the Iris Valve and into the Untie

Receptacle until the bag spout cannot be pulled downward any

further. Do not untie the bag spout string at this time.

Once done, close the Iris Valve, which will seal off the bag spout,

and then untie the string that maintains the bag spout sealed.

Close the hatch of the Untie Receptacle and when ready to discharge

material, open the Iris Valve.

NOTE: The Iris Valve is not intended to close off the flow (discharge)

of material from within a bulk bag by sealing off the bag spout when

the spout is full with material. Please reference Acrison’s Model 820

Bulk Bag Unloader, which is designed to close off the bag spout and

remove a partially empty bag.

Basic Model 821 Bulk Bag Unloader.

2