Page 244 - Flipbook_SolidDesignSoutheast2020

P. 244

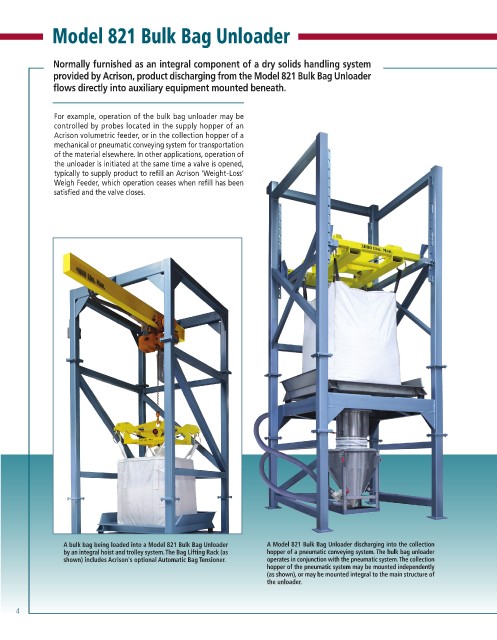

Model 821 Bulk Bag Unloader

Normally furnished as an integral component of a dry solids handling system

provided by Acrison, product discharging from the Model 821 Bulk Bag Unloader

flows directly into auxiliary equipment mounted beneath.

For example, operation of the bulk bag unloader may be

controlled by probes located in the supply hopper of an

Acrison volumetric feeder, or in the collection hopper of a

mechanical or pneumatic conveying system for transportation

of the material elsewhere. In other applications, operation of

the unloader is initiated at the same time a valve is opened,

typically to supply product to refill an Acrison ‘Weight-Loss’

Weigh Feeder, which operation ceases when refill has been

satisfied and the valve closes.

A bulk bag being loaded into a Model 821 Bulk Bag Unloader A Model 821 Bulk Bag Unloader discharging into the collection

by an integral hoist and trolley system. The Bag Lifting Rack (as hopper of a pneumatic conveying system. The bulk bag unloader

shown) includes Acrison's optional Automatic Bag Tensioner. operates in conjunction with the pneumatic system. The collection

hopper of the pneumatic system may be mounted independently

(as shown), or may be mounted integral to the main structure of

the unloader.

4