Page 50 - Flipbook_SolidDesignSoutheast2020

P. 50

Bulk Bag Unloaders

Bulk Bag Unloading for Dry Solids

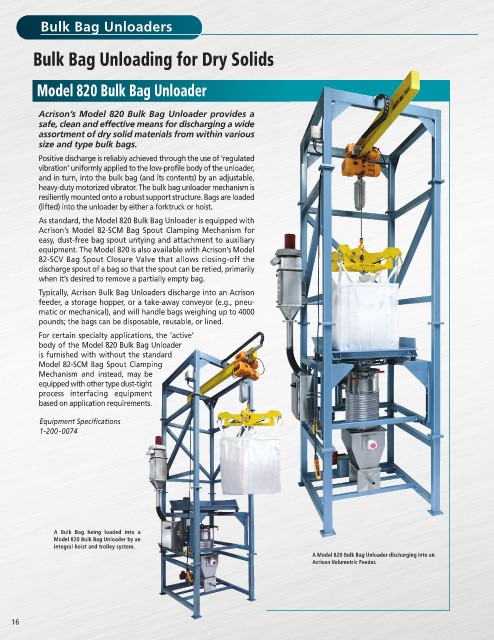

Model820 Bulk Bag Unloader

Acrison’s Model 820 Bulk Bag Unloader provides a

safe, clean and effective means for discharging a wide

assortment of dry solid materials from within various

size and type bulk bags.

Positive discharge is reliably achieved through the use of ‘regulated

vibration’ uniformly applied to the low-profile body of the unloader,

and in turn, into the bulk bag (and its contents) by an adjustable,

heavy-duty motorized vibrator. The bulk bag unloader mechanism is

resiliently mounted onto a robust support structure. Bags are loaded

(lifted) into the unloader by either a forktruck or hoist.

As standard, the Model 820 Bulk Bag Unloader is equipped with

Acrison’s Model 82-SCM Bag Spout Clamping Mechanism for

easy, dust-free bag spout untying and attachment to auxiliary

equipment. The Model 820 is also available with Acrison’s Model

82-SCV Bag Spout Closure Valve that allows closing-off the

discharge spout of a bag so that the spout can be retied, primarily

when it’s desired to remove a partially empty bag.

Typically, Acrison Bulk Bag Unloaders discharge into an Acrison

feeder, a storage hopper, or a take-away conveyor (e.g., pneu-

matic or mechanical), and will handle bags weighing up to 4000

pounds; the bags can be disposable, reusable, or lined.

For certain specialty applications, the ‘active’

body of the Model 820 Bulk Bag Unloader

is furnished with without the standard

Model 82-SCM Bag Spout Clamping

Mechanism and instead, may be

equipped with other type dust-tight

process interfacing equipment

based on application requirements.

Equipment Specifications

1-200-0074

A Bulk Bag being loaded into a

Model 820 Bulk Bag Unloader by an

integral hoist and trolley system.

A Model 820 Bulk Bag Unloader discharging into an

Acrison Volumetric Feeder.

16