Page 33 - UNIDO SECiM - 2020 Highlights

P. 33

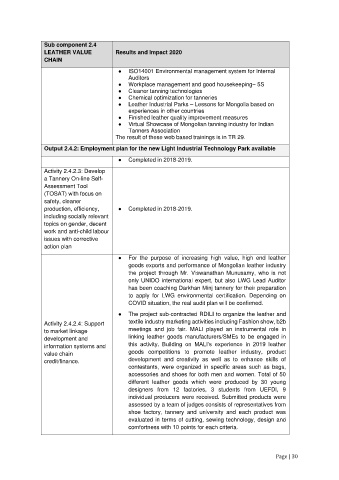

Sub component 2.4

LEATHER VALUE Results and Impact 2020

CHAIN

● ISO14001 Environmental management system for Internal

Auditors

● Workplace management and good housekeeping– 5S

● Cleaner tanning technologies

● Chemical optimization for tanneries

● Leather Industrial Parks – Lessons for Mongolia based on

experiences in other countries

● Finished leather quality improvement measures

● Virtual Showcase of Mongolian tanning industry for Indian

Tanners Association

The result of these web based trainings is in TR 29.

Output 2.4.2: Employment plan for the new Light Industrial Technology Park available

● Completed in 2018-2019.

Activity 2.4.2.3: Develop

a Tannery On-line Self-

Assessment Tool

(TOSAT) with focus on

safety, cleaner

production, efficiency, ● Completed in 2018-2019.

including socially relevant

topics on gender, decent

work and anti-child labour

issues with corrective

action plan

● For the purpose of increasing high value, high end leather

goods exports and performance of Mongolian leather industry

the project through Mr. Viswanathan Munusamy, who is not

only UNIDO international expert, but also LWG Lead Auditor

has been coaching Darkhan Minj tannery for their preparation

to apply for LWG environmental certification. Depending on

COVID situation, the real audit plan will be confirmed.

● The project sub-contracted RDILI to organize the leather and

Activity 2.4.2.4: Support textile industry marketing activities including Fashion show, b2b

to market linkage meetings and job fair. MALI played an instrumental role in

development and linking leather goods manufacturers/SMEs to be engaged in

information systems and this activity. Building on MALI’s experience in 2019 leather

value chain goods competitions to promote leather industry, product

credit/finance. development and creativity as well as to enhance skills of

contestants, were organized in specific areas such as bags,

accessories and shoes for both men and women. Total of 50

different leather goods which were produced by 30 young

designers from 12 factories, 3 students from UEFDI, 9

individual producers were received. Submitted products were

assessed by a team of judges consists of representatives from

shoe factory, tannery and university and each product was

evaluated in terms of cutting, sewing technology, design and

comfortness with 10 points for each criteria.

Page | 30