Page 1 - How to Seat a Brake Line

P. 1

How to SEAT a Brake Line in a Used Component:

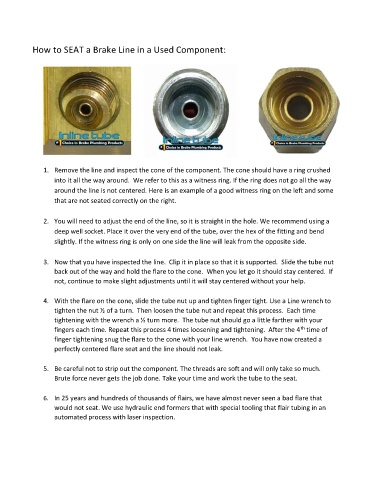

1. Remove the line and inspect the cone of the component. The cone should have a ring crushed

into it all the way around. We refer to this as a witness ring. If the ring does not go all the way

around the line is not centered. Here is an example of a good witness ring on the left and some

that are not seated correctly on the right.

2. You will need to adjust the end of the line, so it is straight in the hole. We recommend using a

deep well socket. Place it over the very end of the tube, over the hex of the fitting and bend

slightly. If the witness ring is only on one side the line will leak from the opposite side.

3. Now that you have inspected the line. Clip it in place so that it is supported. Slide the tube nut

back out of the way and hold the flare to the cone. When you let go it should stay centered. If

not, continue to make slight adjustments until it will stay centered without your help.

4. With the flare on the cone, slide the tube nut up and tighten finger tight. Use a Line wrench to

tighten the nut ½ of a turn. Then loosen the tube nut and repeat this process. Each time

tightening with the wrench a ½ turn more. The tube nut should go a little farther with your

fingers each time. Repeat this process 4 times loosening and tightening. After the 4 time of

th

finger tightening snug the flare to the cone with your line wrench. You have now created a

perfectly centered flare seat and the line should not leak.

5. Be careful not to strip out the component. The threads are soft and will only take so much.

Brute force never gets the job done. Take your time and work the tube to the seat.

6. In 25 years and hundreds of thousands of flairs, we have almost never seen a bad flare that

would not seat. We use hydraulic end formers that with special tooling that flair tubing in an

automated process with laser inspection.