Page 2 - How to Seat a Brake Line

P. 2

How to SEAT a 45 Degree Inverted Flare Brake Line – New Parts

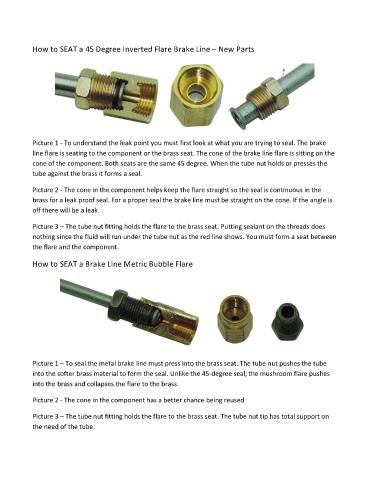

Picture 1 - To understand the leak point you must first look at what you are trying to seal. The brake

line flare is seating to the component or the brass seat. The cone of the brake line flare is sitting on the

cone of the component. Both seats are the same 45 degree. When the tube nut holds or presses the

tube against the brass it forms a seal.

Picture 2 - The cone in the component helps keep the flare straight so the seal is continuous in the

brass for a leak proof seal. For a proper seal the brake line must be straight on the cone. If the angle is

off there will be a leak.

Picture 3 – The tube nut fitting holds the flare to the brass seat. Putting sealant on the threads does

nothing since the fluid will run under the tube nut as the red line shows. You must form a seat between

the flare and the component.

How to SEAT a Brake Line Metric Bubble Flare

Picture 1 – To seal the metal brake line must press into the brass seat. The tube nut pushes the tube

into the softer brass material to form the seal. Unlike the 45-degree seal, the mushroom flare pushes

into the brass and collapses the flare to the brass.

Picture 2 - The cone in the component has a better chance being reused

Picture 3 – The tube nut fitting holds the flare to the brass seat. The tube nut tip has total support on

the need of the tube.