Page 10 - Soitaab Brochure 2-2024

P. 10

Plasma oxyfUeL Waterjet FiBer Laser

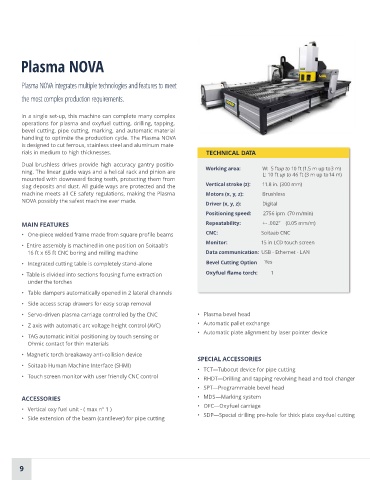

Plasma NOVA

Plasma NOVA integrates multiple technologies and features to meet

the most complex production requirements.

In a single set-up, this machine can complete many complex

operations for plasma and oxyfuel cutting, drilling, tapping,

bevel cutting, pipe cutting, marking, and automatic material

handling to optimize the production cycle. The Plasma NOVA

is designed to cut ferrous, stainless steel and aluminum mate-

rials in medium to high thicknesses. TECHNICAL DATA

Dual brushless drives provide high accuracy gantry positio-

Working area: W: 5 ft up to 10 ft (1.5 m up to 3 m)

ning. The linear guide ways and a helical rack and pinion are

L: 10 ft up to 46 ft (3 m up to 14 m)

mounted with downward facing teeth, protecting them from

slag deposits and dust. All guide ways are protected and the Vertical stroke (z): 11.8 in. (300 mm)

machine meets all CE safety regulations, making the Plasma Motors (x, y, z): Brushless

NOVA possibly the safest machine ever made.

Driver (x, y, z): Digital

Positioning speed: 2756 ipm (70 m/min)

MAIN FEATURES Repeatability: +- .002” (0.05 mm/m)

• One-piece welded frame made from square profile beams CNC: Soitaab CNC

Monitor: 15 in LCD touch screen

• Entire assembly is machined in one position on Soitaab’s

16 ft x 65 ft CNC boring and milling machine Data communication: USB - Ethernet - LAN

• Integrated cutting table is completely stand-alone Bevel Cutting Option Yes

• Table is divided into sections focusing fume extraction Oxyfuel flame torch: 1

under the torches

• Table dampers automatically opened in 2 lateral channels

• Side access scrap drawers for easy scrap removal

• Servo-driven plasma carriage controlled by the CNC • Plasma bevel head

• Z axis with automatic arc voltage height control (AVC) • Automatic pallet exchange

• Automatic plate alignment by laser pointer device

• TAG automatic initial positioning by touch sensing or

Ohmic contact for thin materials

• Magnetic torch breakaway anti-collision device

SPECIAL ACCESSORIES

• Soitaab Human Machine Interface (SHMI)

• TCT―Tubocut device for pipe cutting

• Touch screen monitor with user friendly CNC control

• RHDT―Drilling and tapping revolving head and tool changer

• SPT―Programmable bevel head

ACCESSORIES • MDS―Marking system

• OFC―Oxyfuel carriage

• Vertical oxy fuel unit - ( max n° 1 )

• SDP―Special drilling pre-hole for thick plate oxy-fuel cutting

• Side extension of the beam (cantilever) for pipe cutting

9 10