Page 17 - Soitaab Brochure 2-2024

P. 17

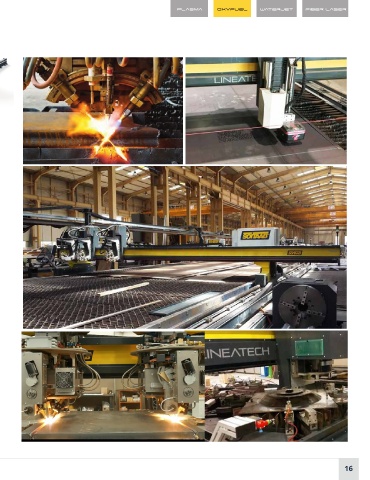

Plasma oxyfUeL Waterjet FiBer Laser

LineaTech NOVA

LineaTech NOVA offers the widest range of solutions for plasma

cutting, oxyfuel, drilling, tapping, and marking.

The modular design allows you to easily add work stations for

oxyfuel or plasma bevel cutting, drilling, tapping, automatic

tool changers, and a variety of plate markers. Dedicated

software developed entirely by Soitaab allows the system

to work in perfect harmony through an intuitive and easy to

use operator interface. The rigid double beam construction

completely protects all linear guides and moving parts.

TECHNICAL DATA

MAIN FEATURES Rail span (min-max): 13 ft up to 23 ft

(4.0 m up to 7.0 m)

• Dual side drive with brushless motors and digital drives

Machine length: 6.5 ft (2.0 m)

• Smooth helical tooth rack with preloaded spring assures

accurate positioning with minimum backlash Machine use length with 4 m rails: 6.5 ft (2.0 m)

• Absolute Encoders hold machine position is held in memory Longitudinal rails beam support: HEB - STD 7 in (180 mm)

• Cutting widths up to 26.3 ft (8.0 m) Transversal beam construction: Double

• Cutting lengths up to 262.5 ft (80.0 m) Transversal guides: Roller-bearing guides

Rack: Helical teeth

• Oxyfuel gas distribution valves fully managed by the CNC

Longitudinal motion: Dual side drives

• Cutting parameter data base adjusts gas pressures and

flows automatically, ensuring high quality cuts and holes Repositioning speed: 787 ipm (20 m/min)

• Automatic electronic ignition Max no. of master carriage: 3

• Automatic height control with both internal and external Max no. of slave carriage (plasma): 2

capacitive probes Max no. of slave carriage (oxy): 12

• LCD control panel with 15 in TFT color touch screen Double master: 2 plasma + 1 oxy

(or combination)

• 78 piece shape library with all cut parameters

Gas distribution (oxy): Automatic

LINEATECH NOVA+ Max cutting thickness (oxy): 10 in – 12 in

(250-300 mm)

All of the features of NOVA but with a reinforced heavy duty

beam for the ISO50 drilling head. Gas for oxy flame: Oxygen, propane,

methane, acetylene

Max plasma power: Up to 800 Amps

ACCESSORIES

Plasma bevel: Yes

• Markers (micro dot, punching, plasma, and powder marking)

Oxy bevel: MR + -90°

• Drilling head with automatic tool changer

Drilling unit type: ISO 30 for prehole

• Graphic cut simulation with complete tool path ISO 40 internal cooling

• Import DXF and DWG files Tool changer type: Automatic (6 or 12)

• Simple and intuitive graphical control menu Tubocut type (pipe cutting): Manual lifting

(automatic optional)

• Sheet alignment, rotation, and scale programs

Pipe diameter: 3 in - 25.5 in

• Remote diagnostics and service 76 mm - 650 mm

• Automatic damper fume extraction

15 16