Page 5 - PBL884 ABB Brochure 3KXA080000R4201 OPERATING INSTRUCTIONS (OI/AZA100-EN)- (12PP Q4 STITCH)

P. 5

AZA100 | UNIVERSAL FLOWCELL | OI/AZA100-EN REV. A PILOT BUILD

5

4 Maintenance Cleaning the flowcell

Interval: Process dependent.

1 Isolate the flowcell from the process.

2 Remove the sensor from the flowcell.

3 Use a brush to clean the inside of flowcell.

4 Install sensor back in the flowcell.

5 Start the flow.

Cleaning the flowcell channels

Interval: Process dependent.

1 Isolate the flowcell from the process.

2 Remove the 1/4 in blanking plugs from the flow channel.

3 If a dual flowcell configuration is in use: Separate the flowcells.

4 Lightly brush the flowcell channels with the bottle brushes supplied in the flowcell maintenance kit.

5 Replace the 1/4 in blanking plugs, and torque them to 8 N·m (5.90 lbf·ft) ±20 %.

6 Start the flow.

Replacing the stirrer

Interval: 2 years (or when necessary).

1 Disconnect the stirrer from the transmitter.

2 Isolate the flowcell from the process.

3 Loosen and remove the stirrer module.

4 Install a new stirrer module. Make sure that the magnetic bar is fitted in the flowcell.

5 Start the flow.

6 Attach the stirrer to the transmitter with an EZLink cable.

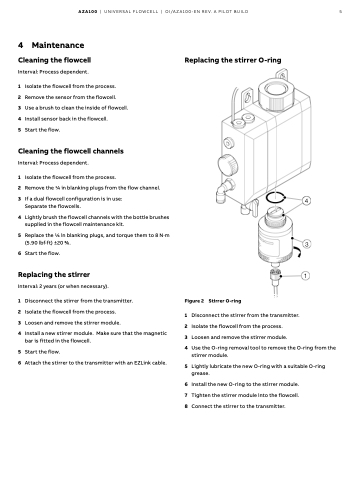

Replacing the stirrer O-ring

4

3

1

4 Use the O-ring removal tool to remove the O-ring from the stirrer module.

5 Lightly lubricate the new O-ring with a suitable O-ring grease.

6 Install the new O-ring to the stirrer module.

7 Tighten the stirrer module into the flowcell.

8 Connect the stirrer to the transmitter.

Figure 2

Stirrer O-ring

1 Disconnect the stirrer from the transmitter.

2 Isolate the flowcell from the process.

3 Loosen and remove the stirrer module.