Page 2 - 1 - Synroof HB Technical Catalogue_Neat

P. 2

.

SYNROOF HI BUILD

Premium Quality Acrylic Waterproof Coating

MECHANICAL PROTECTION 5. Do not clean the cured SYNROOF Hl-

Accessible roofs. The installed BITUMAT BUILD coating with brooms that have

SYNROOF Hl-BUILD can either be covered by hard bristles. These may cause damage.

insitu concrete screed or by thermal insulation. 6. Do not use SYNROOF HI-BUILD on

Place a non-woven polyester separation layer over areas that will be constantly submerged

the acrylic waterproofing membrane followed by in water.

appropriate thermal insulation boards. Then lay

kraft paper or polyethylene sheets as separation CLEAN-UP

layer over the insulation boards and place the As a good roofing practice, flush all hoses,

topping screed of 4cm to Scm thickness or suitable equipment and tools with water immediately

cementtiles. after use.

PACKING

Non - accessible roofs. Place a non-woven . 2okg, metal pails, others on request.

polyester separation layer over the acrylic

waterproofing membrane followed by the insulation STORAGE

boards. Cover the insulation with another layer . Keep away from direct.sunlight and

non-woven polyester separation layer and place preferably store below 30'C and above

15/30 gauge washed gravel to a minimum depth of +5"C

5cm. Forthicker insulation boards, the gravel depth . Protectfrom frost.

should be at leastequal tothatof board thickness. . When stored in unopened containers

expect a minimum shelf life of one year.

PRECAUTIONS

HEALTHANDSAFETY

1 Bitumen or asphalt roof surfaces to receive a L Toxicity - non toxic and odourless.

coating of BITUMAT SYNROOF HI-BUILD Flammability - non flammable when wet.

should be totally dry, Trapped moisture can lead 2. The cured film will burn but is not a fire

to severe oroblems later. hazard.

2. Neverapply if rain is imminent. 3. Skin contact - Prolonged contact is to be

3. Application of thick coat at temperature below avoided. Use of a barrier cream or gloves

+soC may result in incomplete film formation, will orotect sensitive skins.

with reduced elasticity and the possibility of 4. Cleaning - Remove with water when wet

crackforming. and proprietary hand cleanerwhen dry.

Medical assistance - This should be

4 BITUMAT SYNROOF HI-BUILD is resistant to sought if BITUMAT SYNROOF Hl-BUILD

light foot traffic. However heavy traffic, high

heel shoes, furniture etc., will cause damage. is ingested or rinsed with copious amount

ln these cases the membrane should be of clean water.

protected bytiles, slabs. etc. o Ventilation to the working area is

desirable.

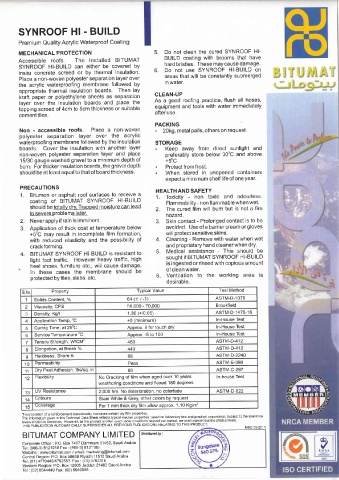

SNo Property Typical Value Test Method

1 Solids Content, % 64 (+ t -1) ASTM.D-1076

z Viscosity, CPS 50,000 - 70,000 Brookfield

Density, Kg/l 1 30 (+/0.05) ASTM-D-1475-16

oC +5 (minimum) ln-House Tesl

4 Application Temp,

Curing Time, at25oC Approx. B for touch dry ln-House Test

o Service Temoerature "C Approx. -5 to 100 ln-House Test

7 Tensile Strength, W/CM' 480 ASTM-D-412

8 Elongation, at Break o/o 440 ASTM-D.412

I Hardness, ShoreA 68 ASTM-D-2240

10 Permeability Pass ASTM_E-398

Dry Peel Adhesion, lbs/sq. in ASTM-C-297

11

Flexibility No Cracking of film when aged over 10 years ln-house Test

12

weathering conditions and flexed 180 degrees

UV Resistance 2,000 hrs. No deterioration, no colorfade ASTM-D-822

13

Colours Stain White & Grey, other colors by request

14

16 Coverage For 1 mm thick dry film allow approx. 1 10 Kg/m'

*lncorooration of a reinforcement considerably increases certain drv film properties

Tha lnf6rmelion diven in this Technical Data Sheet reflects tvDical median propertieproperties based on laboratory test and practical experiencg; subject to the tolerance

reflects tvDical median

The Information given in this Technical

levelsofUEAtoAirectives However,astheproductisoftenusedunderconditionsbeyondourcontrol,wecan'twarrantbuttheproductltselr

inis pueLtclrroNt nuroH.lnrtcarlv supEnseoes nrr pREVtous PUBLtcATIoNS RELATING To rHls PRoDUcT. MSD 05/2014

BITUMAT COMPANY LIMITED Disttibuted by :

Corporate Office : P O Box7487 Dammam 31462, Saudi Arabia

Tel: (966-3) 8121210 Fax : (966-3) 8121190

Website : www.bitumat.com / email: marketing@bitumat.com

Central Region: P.O Box 58698 Riyadh 1 1 51 5 Saudi Arabia

];et: (O1l 477044314792553 Fax : (01 ) 4762318

Western Region: P.O. Box 12605 Jeddah 21483 Saudi Arabia

Tel : (02) 6644449 Fax: (02) 6640506