Page 15 - Buy Premium Tools ATORN Catalogue

P. 15

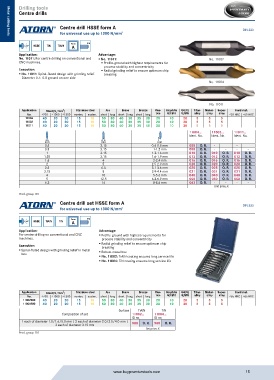

Drilling tools

Centre drills

Centre drill HSSE form A DIN 333

for universal use up to 1300 N/mm 2

Metal cutting tools

Metal cutting tools

Form HA

HSSE TiN TiAlN A

Application: Advantage:

No. 11011: For centre drilling on conventional and No. 11011: No. 11002

CNC machines. Profile-ground with highest requirements for

process stability and concentricity

Execution: Radial grinding relief to ensure optimum chip

No. 11011: Spiral-fluted design with grinding relief. breaking

Diameter 0.5–0.8 ground on one side

No. 11004

No. 11011

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11004 40 20 20 15 10 50 80 40 30 35 30 20 10 20 5 5 5

11002 40 20 20 15 10 50 80 40 30 35 30 20 10 20 5 5 5

11011 40 20 20 15 10 50 80 40 30 35 40 20 10 20 5 5 5

11004... 11002... 11011...

Ident. No. Ident. No. Ident. No.

mm mm mm

0.5 3.15 0.6-0.8 mm 005 O. R. - - - -

0.8 3.15 1-1.2 mm 008 O. R. - - - -

1 3.15 1.3-1.6 mm 010 O. R. 010 O. R. 010 O. R.

1.25 3.15 1.6-1.9 mm 012 O. R. 012 O. R. 012 O. R.

1.6 4 2-2.4 mm 016 O. R. 016 O. R. 016 O. R.

2 5 2.5-2.9 mm 020 O. R. 020 O. R. 020 O. R.

2.5 6.3 3.1-3.6 mm 025 O. R. 025 O. R. 025 O. R.

3.15 8 3.9-4.4 mm 031 O. R. 031 O. R. 031 O. R.

4 10 5-5.6 mm 040 O. R. 040 O. R. 040 O. R.

5 12.5 6.3-6.9 mm 050 O. R. 050 O. R. 050 O. R.

6.3 16 8-8.6 mm 063 O. R. - - - -

Unit price, €

Prod. group 101

Centre drill set HSSE form A

for universal use up to 1300 N/mm 2 DIN 333

Form HA

HSSE TiAlN TiN A

Application: Advantage:

For centre drilling on conventional and CNC Profile-ground with highest requirements for

machines. process stability and concentricity

Execution: Radial grinding relief to ensure optimum chip

breaking

Spiral-fluted design with grinding relief in metal Robust metal box

box

No. 11002: TiAlN coating ensures long service life

No. 11004: TiN coating ensures long service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11002900 40 20 20 15 10 50 80 40 30 35 30 20 10 20 5 5 5

11004900 40 20 20 15 10 50 80 40 30 35 30 20 10 20 5 5 5

Surface TiAlN TiN

Composition of set 11002... 11004...

ID no. ID no.

1 each of diameter 1.0/1.6/5.0 mm | 2 each of diameter 2.0/2.5/4.0 mm | 900 O. R. 900 O. R.

3 each of diameter 3.15 mm

Set price, €

Prod. group 101

www.buypremiumtools.com 15