Page 18 - Buy Premium Tools ATORN Catalogue

P. 18

Drilling tools

NC spotting drill

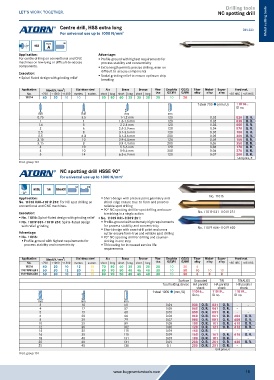

Centre drill, HSS extra long DIN 333 Metal cutting tools

For universal use up to 1000 N/mm 2

Form HA

HSS A

Application: Advantage:

For centre drilling on conventional and CNC Profile-ground with highest requirements for

machines on low-lying or difficult-to-access process stability and concentricity

components. Extra length permits precise drilling, even on

Execution: difficult-to-access components

Spiral-fluted design with grinding relief Radial grinding relief to ensure optimum chip

breaking

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11014 40 20 10 10 50 80 40 35 35 30 20 10 20

f steel 700 (mm/U) 11014...

ID no.

mm mm mm mm

0.75 3.5 1-1.2 mm 120 0.02 020 O. R.

1 4 1.3-1.6 mm 120 0.02 030 O. R.

1.6 5 2-2.4 mm 120 0.03 050 O. R.

2 6 2.5-2.9 mm 120 0.04 070 O. R.

2.5 8 3.1-3.6 mm 120 0.05 100 O. R.

2.5 6.3 3.1-3.6 mm 200 0.05 300 O. R.

3.15 10 3.9-4.4 mm 120 0.05 150 O. R.

3.15 8 3.9-4.4 mm 200 0.05 350 O. R.

4 10 5-5.6 mm 120 0.06 170 O. R.

4 10 5-5.6 mm 200 0.06 370 O. R.

5 14 6.3-6.9 mm 120 0.07 200 O. R.

Unit price, €

Prod. group 101

NC spotting drill HSSE 90°

for universal use up to 1300 N/mm 2

HA HB

HSSE TiN TiNAlOX

90°

Application: Short design with precise point geometry and No. 11016

No. 11016 030–11019 251: For NC spot drilling on chisel edge ensure true-to-form and process-

conventional and CNC machines. reliable spot drilling

90° NC spotting drill for spot drilling and coun-

Execution: tersinking in a single action No. 11019 031–11019 251

No. 11016: Spiral-fluted design with grinding relief No. 11019 031–11019 251:

No. 11019 031–11019 251: Spiral-fluted design Profile-ground with extremely high requirements

with relief grinding for process stability and concentricity No. 11019 606–11019 620

Short design with exact drill point and cross-

Advantage: cutter ensure form-true and reliable spot drilling

No. 11016: 90° NC spotting drill for drilling and counter-

Profile-ground with highest requirements for sinking in one step

process stability and concentricity TiN coating for increased service life

requirements

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11016 40 20 10 12 10 70 80 40 35 35 30 20 10 20 6

11019031-251 50 30 12 20 15 80 90 50 40 45 40 30 10 30 10 10 10

11019606-620 50 30 10 20 15 80 90 50 40 45 40 30 10 30 8 8 8

Surface Uncoated TiN TiNALOX

Tool holding device HA parallel HA parallel HB parallel

shank shank shank

f steel 1000 (mm/U) 11016... 11019... 11019...

ID no. ID no. ID no.

mm mm mm

3 10 50 0.04 030 O. R. 031 O. R. - -

4 12 52 0.05 040 O. R. 041 O. R. - -

5 15 60 0.05 050 O. R. 051 O. R. - -

6 20 66 0.06 060 O. R. 061 O. R. 606 O. R.

8 25 79 0.07 080 O. R. 081 O. R. 608 O. R.

10 25 89 0.08 100 O. R. 101 O. R. 610 O. R.

12 30 102 0.08 120 O. R. 121 O. R. 612 O. R.

14 35 115 0.09 140 O. R. - - - -

16 35 115 0.09 160 O. R. 161 O. R. 616 O. R.

18 40 131 0.09 180 O. R. 181 O. R. - -

20 40 131 0.09 200 O. R. 201 O. R. 620 O. R.

25 45 138 0.1 250 O. R. 251 O. R. - -

Unit price, €

Prod. group 101

www.buypremiumtools.com 18