Page 294 - Icon Ridge Presents ORION

P. 294

Turning tools \ Technical introduction – CBN turning

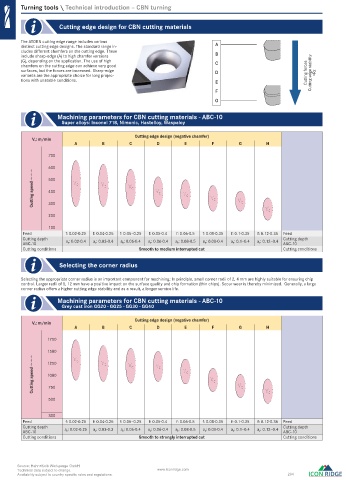

Cutting edge design for CBN cutting materials

The ATORN cutting edge range includes various

distinct cutting edge designs. The standard range in- A

cludes different chamfers on the cutting edge. These

include sharp-edge (A) to high chamfer versions B

(G), depending on the application. The use of high

chamfers on the cutting edge can achieve very good C

surfaces, but the forces are increased. Sharp-edge D

variants are the appropriate choice for long projec- Cutting forces Cutting edge stability <Rz

tions with unstable conditions. E

F

G

Machining parameters for CBN cutting materials - ABC-10

Super alloys: Inconel 718, Nimonic, Hastelloy, Waspaloy

Cutting edge design (negative chamfer)

V c: m/min

A B C D E F G H

700

600

Cutting speed → → → 500 V c V c V c V c V c V

400

c

V

c

300

V c

200

100

Feed f: 0.02-0.25 f: 0.04-0.25 f: 0.05–0.25 f: 0.05-0.4 f: 0.06-0.5 f: 0.08-0.35 f: 0.1-0.35 f: 0.12-0.35 Feed

Cutting depth a p: 0.02-0.4 a p: 0.03-0.4 a p: 0.06-0.4 a p: 0.06-0.4 a p: 0.08-0.5 a p: 0.08-0.4 a p: 0.1–0.4 a p: 0.12–0.4 Cutting depth

ABC-10 ABC-10

Cutting conditions Smooth to medium interrupted cut Cutting conditions

Selecting the corner radius

Selecting the appropriate corner radius is an important component for machining: In principle, small corner radii of 2, 4 mm are highly suitable for ensuring chip

control. Larger radii of 8, 12 mm have a positive impact on the surface quality and chip formation (thin chips). Scour wear is thereby minimized. Generally, a large

corner radius offers a higher cutting edge stability and as a result, a longer service life.

Machining parameters for CBN cutting materials - ABC-10

Grey cast iron GG20 - GG25 - GG30 - GG40

Cutting edge design (negative chamfer)

V c: m/min

A B C D E F G H

1750

1500 V c V

Cutting speed → → → 1000 c V c V c V c V c V c

1250

750

500 V c

300

Feed f: 0.02-0.25 f: 0.04-0.25 f: 0.05–0.25 f: 0.05-0.4 f: 0.06-0.5 f: 0.08-0.35 f: 0.1-0.35 f: 0.12-0.35 Feed

Cutting depth a p: 0.02-0.25 a p: 0.03-0.3 a p: 0.06-0.4 a p: 0.06-0.4 a p: 0.08-0.5 a p: 0.08-0.4 a p: 0.1–0.4 a p: 0.12–0.4 Cutting depth

ABC-10 ABC-10

Cutting conditions Smooth to strongly interrupted cut Cutting conditions

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 294

0576_EN_2018_KERN[21847876]-l.indd 576 12/17/2018 3:33:08 PM