Page 15 - Instrumentation and Measurement

P. 15

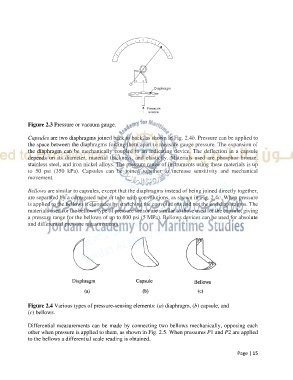

Figure 2.3 Pressure or vacuum gauge.

Capsules are two diaphragms joined back to back, as shown in Fig. 2.4b. Pressure can be applied to

the space between the diaphragms forcing them apart to measure gauge pressure. The expansion of

the diaphragm can be mechanically coupled to an indicating device. The deflection in a capsule

depends on its diameter, material thickness, and elasticity. Materials used are phosphor bronze,

stainless steel, and iron nickel alloys. The pressure range of instruments using these materials is up

to 50 psi (350 kPa). Capsules can be joined together to increase sensitivity and mechanical

movement.

Bellows are similar to capsules, except that the diaphragms instead of being joined directly together,

are separated by a corrugated tube or tube with convolutions, as shown in Fig. 2.4c. When pressure

is applied to the bellows it elongates by stretching the convolutions and not the end diaphragms. The

materials used for the bellows type of pressure sensor are similar to those used for the capsule, giving

a pressure range for the bellows of up to 800 psi (5 MPa). Bellows devices can be used for absolute

and differential pressure measurements.

Figure 2.4 Various types of pressure-sensing elements: (a) diaphragm, (b) capsule, and

(c) bellows.

Differential measurements can be made by connecting two bellows mechanically, opposing each

other when pressure is applied to them, as shown in Fig. 2.5. When pressures P1 and P2 are applied

to the bellows a differential scale reading is obtained.

Page | 15